Building a Shock-Proof Workplace: Strategies for Implementing Successful Electrical Safety Audits in Indian Industries

Proactive Measures for Fire Prevention: Implementing Fire Safety Audits in Indian Industries

November 27, 2024

A Comprehensive Guide to Developing Process Safety Information for Process Industries in India

December 3, 2024In this article, we delve into the crucial topic of electrical safety audits in Indian industries, where implementing effective strategies is the key to building a shock-proof workplace. As workplace accidents related to electrical hazards continue to pose a serious threat, it has become imperative for organizations across the country to prioritize safety. We will explore the common challenges faced, discuss strategies to overcome them, and offer practical solutions for successful implementation. So, if you are eager to safeguard your workforce and ensure compliance with safety regulations, stay tuned. Get ready to equip yourself with invaluable knowledge that promises a secure and prosperous future for your organization.

Importance of Electrical Safety Audits in Indian Industries

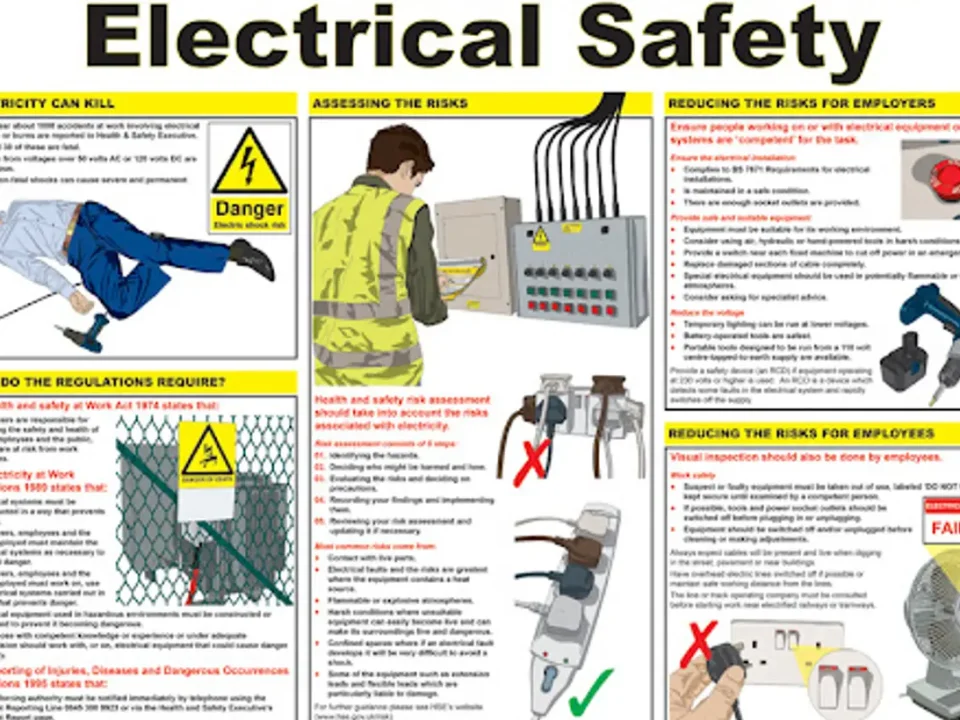

In the intricate tapestry of Indian industries, the importance of electrical safety audits cannot be overstated. With a rapidly growing economy and a burgeoning workforce, ensuring the well-being of employees is paramount. These audits serve as a vital tool to identify potential electrical hazards and mitigate risks effectively. By diligently assessing electrical systems, equipment, and procedures, organizations can create a shock-proof workplace that not only safeguards their personnel but also fosters an environment conducive to productivity and growth. The need for electrical safety audits arises from the inherent dangers associated with electricity. India’s industrial landscape witness’s countless incidents of electrical mishaps each year, resulting in injuries, fatalities, and massive financial losses. Through comprehensive audits, companies can proactively address potential hazards such as faulty wiring, overloads, inadequate grounding systems, or outdated equipment. By identifying these risks beforehand and implementing appropriate control measures, organizations exhibit their commitment to employee welfare while safeguarding their own financial stability.

Moreover, embracing electrical safety audits demonstrates an organization’s compliance with legal regulations set forth by Indian authorities. The Electricity Act of 2003 mandates that all industries adhere to specific norms regarding installation, operation, and maintenance of electrical systems. By conducting regular audits aligned with these standards and codes prescribed by regulatory bodies such as the Bureau of Indian Standards (BIS), companies not only ensure legal compliance but also establish themselves as responsible corporate citizens dedicated to creating a secure working environment.

By prioritizing electrical safety audits in Indian industries, organizations embark on a transformative journey towards fostering an optimistic culture cantered around employee well-being. Through these proactive measures to mitigate electrical risks comprehensively at all levels – from risk assessment to incident reporting – companies actively foster trust and loyalty among their workforce while bolstering their reputation in the market

Understanding the Legal Framework for Electrical Safety in India

India, a nation renowned for its rich historical tapestry and vibrant cultural heritage, also places great emphasis on ensuring the safety of its workforce in various industries. To navigate the intricate web of electrical safety regulations in this vast land, one must delve into the realm of legal frameworks that govern workplace safety. The core legislation in this domain is the Electricity Act of 2003, which establishes a comprehensive framework for electrical safety standards and regulations across all sectors. Under this Act, the Central Electricity Authority (CEA) has been bestowed with the responsibility of formulating national policies and guidelines to promote a secure electrical environment. Additionally, various state governments have enacted their own rules to supplement these national provisions, aiming to ensure compliance at a local level. Understanding this complex legal landscape is paramount to effectively conducting electrical safety audits within Indian industries.

Moreover, it is crucial to comprehend specific statutory obligations pertaining to electrical installations and equipment maintenance. These encompass regulations related to earthing systems, circuit protection devices, testing procedures, and certification requirements. By familiarizing themselves with these legal obligations and staying abreast of any amendments or updates issued by regulatory bodies such as the Bureau of Indian Standards (BIS), organizations can ensure that their workplaces remain equipped with fool proof electrical safety measures.

Gone are the days when electric shocks plagued Indian industries; today’s legal framework empowers businesses to cultivate an electrifying work environment that prioritizes employee well-being. By embracing these regulations as catalysts for growth rather than constraints on operations, companies can foster an optimistic culture where every individual feels confident operating within a shock-proof workplace.

Conducting a Thorough Risk Assessment for Electrical Hazards

Conducting a Thorough Risk Assessment for Electrical Hazards: As we embark on the journey of building a shock-proof workplace, conducting a comprehensive risk assessment for electrical hazards takes centre stage. This crucial step enables us to identify and evaluate potential risks that can lead to electrical accidents or malfunctions within our industrial establishments in India. By meticulously examining each aspect of our electrical systems, we unveil vulnerabilities that may have remained hidden, thereby empowering us to take proactive measures and prevent unpleasant surprises.

During the risk assessment process, experts meticulously inspect all elements of the electrical infrastructure: from power sources and distribution panels to wiring systems and equipment grounding. Each component is examined with meticulous attention to detail, leaving no stone unturned in our quest for safety excellence. By employing cutting-edge technology and utilizing specialized instruments, we can accurately measure electrical parameters such as voltage, current flow, insulation resistance levels, ground fault potential, and more.

Such meticulous examination allows us to gain a comprehensive understanding of the risks inherent in our electrical systems. Armed with this knowledge, we can then develop targeted strategies to mitigate these risks effectively. Through risk prioritization and hazard mapping exercises, we identify critical areas that require immediate attention while also planning for long-term improvements. This methodical approach ensures that every potential hazard is addressed efficiently and systematically

Creating an Effective Electrical Safety Policy

Creating an Effective Electrical Safety Policy: Crafting a comprehensive and robust electrical safety policy is paramount to ensuring a shock-proof workplace in Indian industries. This pivotal document lays the foundation for a culture of safety, outlining the guidelines, procedures, and responsibilities pertaining to electrical hazards. It serves as a compass that navigates organizations towards compliance with legal requirements and industry best practices.

An effective electrical safety policy should encompass various elements. Firstly, it must define the objectives and scope of the policy, emphasizing the organization’s commitment to safeguarding its workforce against electrical risks. Additionally, it should provide clear guidelines on risk assessment methodologies, detailing how potential hazards will be identified and evaluated within the organization’s specific context.

Furthermore, an exemplary policy outlines the roles and responsibilities of different stakeholders involved in maintaining electrical safety. It affirms management’s commitment to providing adequate resources for training employees on safe practices while assigning accountability for implementing preventive measures. By fostering collaboration between management and workers, such policies empower individuals through shared responsibility, promoting a sense of ownership over workplace safety.

Overall, an effective electrical safety policy instils confidence among employees by demonstrating an unwavering dedication to their well-being. With this proactive approach in place, organizations can effectively minimize risks associated with electricity usage while cultivating a positive work environment that values both productivity and personnel welfare.

Training Employees on Electrical Safety Practices

Section: Training Employees on Electrical Safety Practices Ingraining a safety-first mind-set within the workforce is paramount to building a shock-proof workplace. Training employees on electrical safety practices equips them with the knowledge and skills necessary to identify potential hazards and mitigate risks effectively. An engaging training program should cover topics such as electrical equipment handling, safe work practices, proper use of personal protective equipment (PPE), and emergency response procedures.

Through interactive workshops and hands-on demonstrations, employees can grasp the intricacies of electrical safety with ease. By highlighting real-life examples and case studies, trainers can create a relatable learning environment that promotes active participation. Emphasizing the value of collective responsibility in maintaining a safe working environment fosters an optimistic culture where every individual feels empowered to contribute towards preventing accidents and promoting well-being.

Remember, effective training is an ongoing process that should be integrated into periodic refresher courses to ensure knowledge retention. By investing in comprehensive training programs, organizations not only minimize the risk of electrical incidents but also instil confidence among employees, assuring them that their safety is indeed valued. Ultimately, a well-trained workforce acts as the cornerstone for building resilience against electrical hazards within Indian industries.

Selecting the Right Tools and Equipment for Safety Audits

Enter the section Selecting the Right Tools and Equipment for Safety Audits: In order to conduct successful electrical safety audits, it is crucial to equip oneself with the right tools and equipment that will enhance efficiency, accuracy, and safety. One indispensable tool is the digital mustimeter – a versatile instrument capable of measuring various electrical parameters such as voltage, current, and resistance. Its ergonomic design allows for easy handling and its precise readings ensure accurate diagnosis of potential hazards. Furthermore, investing in a high-quality insulation resistance tester not only enables the evaluation of insulation integrity but also aids in identifying leakage currents that could lead to electrical shocks or fires.

Another essential item for safety audits is an infrared thermal imaging camera. This revolutionary device permits thorough inspections by detecting hotspots or abnormal temperature patterns within electrical systems. By utilizing this technology, potential risks such as overloaded circuits or faulty connections can be identified before they escalate into hazardous incidents. Additionally, incorporating a portable appliance tester (PAT) into your toolkit facilitates comprehensive testing of appliances and their cords for any signs of wear or malfunction.

By thoughtfully selecting these advanced tools and equipment for safety audits, Indian industries can stay at the forefront of electrical safety practices. Not only will this promote a safer work environment but it will also increase productivity by preventing downtime caused by accidents or equipment failure

Ensuring Compliance with Electrical Standards and Codes

Amidst the intricate web of electrical regulations, compliance becomes paramount to foster a shock-proof workplace. Indian industries must align themselves with the ever-evolving electrical standards and codes set forth by regulatory bodies such as the Bureau of Indian Standards (BIS) and the Central Electricity Authority (CEA). Adhering to these guidelines not only safeguards employees’ lives but also showcases an organization’s commitment towards excellence in safety. It is imperative for companies to meticulously evaluate their electrical systems, equipment, and installations against the relevant standards, ensuring every aspect meets or exceeds the stipulated requirements. By doing so, they pave the path towards a resilient work environment that fosters trust and confidence among both employees and stakeholders. Moreover, embracing compliance goes beyond mere legal obligations; it signifies an organization’s dedication to upholding ethical practices while mitigating risks associated with electrical hazards. Stringent adherence to standards ensures that electrical systems are designed, operated, and maintained in a manner that minimizes potential dangers. Regular audits should scrutinize all elements of an establishment’s electrical infrastructure – right from wiring arrangements to protective devices – ensuring they conform harmoniously to established codes. This proactive approach instils a sense of security within employees while enhancing their productivity, leading to sustained growth for businesses.

In this pursuit of compliance-driven excellence, industries should also keep themselves up-to-date with any amendments or enhancements made in electrical standards over time. This continual process allows organizations to remain at the forefront of innovation while consistently fortifying their safety measures against emerging threats

Regular Inspections and Maintenance of Electrical Systems and Equipment

Regularly inspecting and maintaining electrical systems and equipment is paramount when building a shock-proof workplace. A diligent approach to these tasks ensures that potential hazards are identified and rectified promptly, minimizing the risk of electrical accidents. During inspections, all components and connections are thoroughly examined for signs of wear, damage, or improper functioning. Additionally, routine maintenance procedures such as cleaning, lubrication, and calibration are carried out meticulously to optimize performance and longevity. By adhering to a rigorous inspection and maintenance schedule, organizations demonstrate their commitment to employee safety while also safeguarding their assets. This proactive approach fosters a sense of security among workers who can trust that the electrical systems they interact with daily have undergone thorough scrutiny. Moreover, regular inspections offer an opportunity for ongoing improvement as any issues identified can be addressed promptly through necessary repairs or replacements. Ultimately, this diligent practice contributes to the creation of a culture where safety is prioritized at all levels of the organization.

In addition to mitigating risks and enhancing safety measures, regular inspections and maintenance also yield financial benefits. By detecting potential issues early on through proactive examinations, costly breakdowns or disruptions can be prevented. Furthermore, well-maintained electrical systems operate more efficiently, reducing energy consumption and associated utility costs. This not only contributes positively to an organization’s bottom line but also promotes sustainability by minimizing environmental impact.

In conclusion, implementing regular inspections and maintenance protocols for electrical systems is crucial in constructing a shock-proof workplace in Indian industries. By embracing this comprehensive approach consistently, organizations establish robust safety practices while reaping both tangible financial gains and intangible benefits like employee peace of mind

Implementing Effective Incident Reporting and Investigation Procedures

Implementing Effective Incident Reporting and Investigation Procedures: In the realm of electrical safety, incidents may occur despite preventive measures. Therefore, it is crucial for Indian industries to establish robust incident reporting and investigation procedures. The objective is not merely to assign blame but rather to identify the root causes of accidents and prevent their recurrence.

When an incident occurs, the first step is prompt reporting. Employees should be encouraged to report any potential hazards or accidents without fear of reprisal. This open communication fosters a culture of safety where all employees feel valued for their contribution to creating a shock-proof workplace.

Once an incident is reported, a thorough investigation must commence. Trained professionals equipped with specialized tools meticulously examine the scene, documenting evidence and collecting data to analyse the sequence of events leading up to the incident. This comprehensive investigation process ensures that no stone is left unturned in identifying contributing factors and finding ways to rectify them.

Effective incident reporting and investigation procedures serve as invaluable learning experiences for organizations. They provide valuable insights into system weaknesses or human errors that can be rectified through process improvements or additional training measures. By embracing a proactive approach towards incident response, Indian industries pave the way for continuous improvement in electrical safety practices and inspire confidence in their employees that their well-being matters above all else.

Engaging Employees in an Ongoing Safety Culture

Engaging Employees in an Ongoing Safety Culture: Encouraging employee participation is crucial for creating a robust safety culture within Indian industries. It begins by fostering a sense of ownership and accountability among the workforce. By organizing interactive training sessions, employees can be educated about the importance of adhering to electrical safety protocols. Emphasizing the potential risks and positive outcomes associated with a safe workplace encourages active engagement.

To further promote employee participation, implementing recognition programs can prove highly effective. Recognizing individuals or teams for their commitment to safety not only boosts morale but also instils a sense of pride and motivation within the workforce. Moreover, encouraging employees to share their insights and suggestions on improving safety measures fosters a collaborative environment where everyone feels valued for their contributions.

Creating open channels of communication is vital in maintaining an ongoing safety culture. Regular meetings or toolbox talks provide opportunities for employees to voice concerns, ask questions, and exchange knowledge about electrical safety practices. By actively listening to their experiences and addressing any issues promptly, organizations foster trust which leads to increased dedication towards building a shock-proof workplace.

Remember, when employees actively participate in cultivating a strong safety culture, they become ambassadors for change – spreading awareness beyond the workplace and positively impacting society as a whole.

Outcome and Benefits of Successful Electrical Safety Audits in Indian Industries

Outcome and Benefits of Successful Electrical Safety Audits in Indian Industries: When electrical safety audits are conducted diligently in Indian industries, the outcomes and benefits are manifold. Firstly, incidents of electrical accidents and injuries are significantly reduced, ensuring the well-being and physical integrity of workers. This not only promotes a safe working environment but also fosters higher employee morale and productivity. Furthermore, successful electrical safety audits enhance the reputation of companies, instilling confidence in clients and stakeholders who can trust that their interests are safeguarded.

Moreover, these audits lead to improved compliance with regulatory standards, avoiding penalties and legal complications. By identifying potential hazards proactively, industries can mitigate risks effectively and prevent costly equipment damage due to electrical malfunctions. Additionally, successful audits facilitate better resource allocation as companies can allocate budgets more efficiently towards maintaining electrical systems rather than dealing with expensive emergency repairs or replacements.

Ultimately, implementing successful electrical safety audits creates an overall culture of safety within Indian industries. It empowers employees to take responsibility for their own well-being while fostering a sense of trust between management and workers. By prioritizing the protection of human life over profits, companies demonstrate their commitment to upholding ethical practices that resonate positively with customers and investors alike.

Conclusion

In conclusion, by diligently implementing successful electrical safety audits in Indian industries, we can pave the way for a shock-proof workplace, where employees feel secure and confident in their surroundings. The comprehensive risk assessment and meticulous adherence to electrical standards and codes ensure that potential hazards are identified and mitigated efficiently. Regular inspections, maintenance, and incident reporting procedures further contribute to a culture of safety. As organizations engage employees in this ongoing journey towards electrical safety excellence, they foster an environment that nurtures growth, productivity, and peace of mind. By investing in these strategies today, we can build a brighter tomorrow for all stakeholders involved.