Electrical Safety Audit: Identifying and Mitigating Arc Flash Risks in the Workplace & Addressing Compliance Issues

Electrical Hazards and Safety: Types, Dangers, and Examples

January 21, 2025

Unlocking Safety: The Importance of Modern Process Hazard Analysis (PHA)

January 23, 2025In today’s industrial and commercial environments, electrical safety is a critical concern. Among the many hazards that can occur in the workplace, arc flash incidents are particularly dangerous. These sudden releases of electrical energy can cause severe injury or even death, and they pose significant risks to both employees and equipment. An effective electrical safety audit can help identify and mitigate these risks while ensuring compliance with relevant regulations. At The Safety Master, we believe that a proactive approach to electrical safety can safeguard your workplace from the devastating effects of arc flash incidents.

What Is an Electrical Safety Audit, and Why Is It Important?

An electrical safety audit is a systematic evaluation of electrical systems, equipment, and practices within an organization. The purpose of the audit is to identify potential hazards, assess the effectiveness of existing safety measures, and ensure compliance with electrical safety regulations.

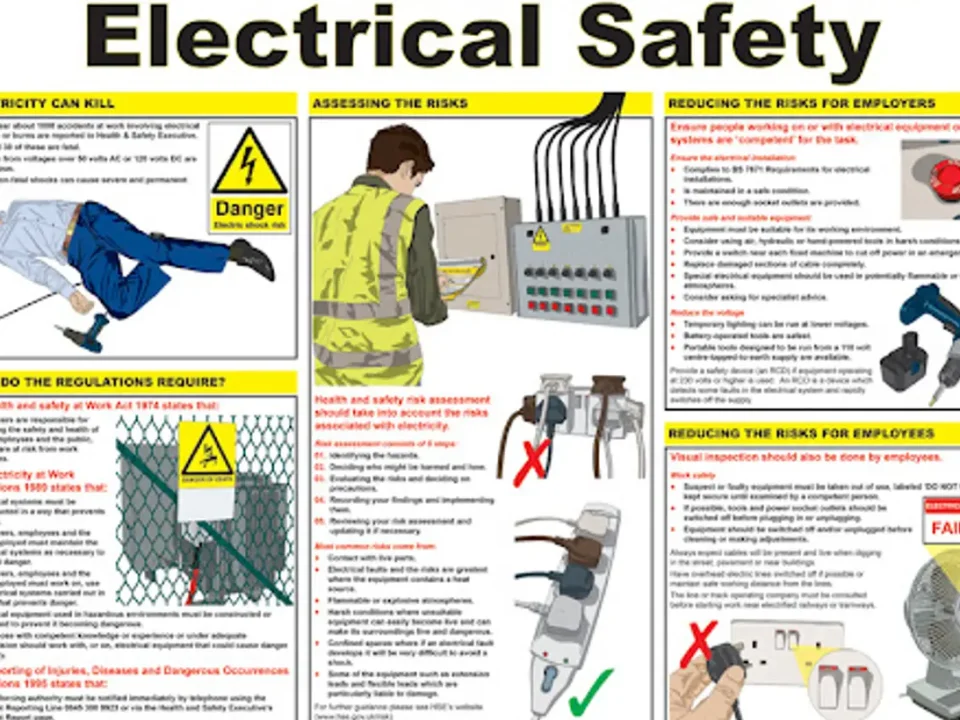

- Identifying Electrical Hazards: Electrical safety audits focus on identifying a wide range of electrical hazards, including faulty wiring, inadequate grounding, overloaded circuits, and, most importantly, arc flash risks. By pinpointing these hazards, organizations can take steps to mitigate them before they result in accidents or injuries.

- Assessing Safety Measures: The audit also evaluates the effectiveness of current safety measures, such as personal protective equipment (PPE), lockout/tagout procedures, and training programs. This assessment helps ensure that safety protocols are being followed and that they are adequate to protect employees from electrical hazards.

- Ensuring Compliance: Compliance with electrical safety regulations is a legal requirement in most industries. An electrical safety audit ensures that your organization is meeting all necessary regulatory requirements, reducing the risk of fines, penalties, and legal liabilities.

- Promoting a Culture of Safety: Beyond compliance, an electrical safety audit fosters a culture of safety within the organization. By regularly evaluating and improving electrical safety practices, organizations can create an environment where safety is prioritized, and employees are empowered to take ownership of their safety responsibilities.

What Are Arc Flash Risks, and Why Are They Dangerous?

Arc flash incidents occur when an electrical current travels through the air between two conductors, resulting in a sudden and violent release of energy. This energy can produce extreme heat, intense light, and pressure waves, all of which can cause severe injuries, including burns, blindness, and hearing damage. In addition to the human impact, arc flash incidents can also cause significant damage to equipment and facilities.

- Heat and Burns: The temperatures generated by an arc flash can reach up to 35,000 degrees Fahrenheit, causing severe burns and even igniting clothing. These burns can be life-threatening and require extensive medical treatment.

- Pressure Waves: The rapid expansion of air caused by the intense heat of an arc flash creates a pressure wave that can throw workers across a room, causing physical injuries such as broken bones and concussions.

- Explosive Debris: The force of an arc flash can propel molten metal and other debris at high speeds, increasing the risk of injury to anyone in the vicinity.

- Damage to Equipment: Arc flash incidents can cause extensive damage to electrical equipment, resulting in costly repairs, downtime, and potential loss of production.

Given these risks, it is essential for organizations to take proactive measures to identify and mitigate arc flash hazards in the workplace.

How Can an Electrical Safety Audit Help Identify Arc Flash Risks?

An electrical safety audit plays a crucial role in identifying arc flash risks in the workplace. The audit involves a comprehensive evaluation of electrical systems, equipment, and practices to pinpoint areas where arc flash incidents are more likely to occur.

- System Evaluation: The audit begins with a thorough evaluation of the electrical system, including transformers, circuit breakers, panels, and other equipment. This evaluation helps identify potential arc flash hazards, such as loose connections, damaged insulation, or improper equipment ratings.

- Arc Flash Risk Assessment: The audit includes an arc flash risk assessment, which calculates the potential energy release in the event of an arc flash. This assessment helps determine the appropriate PPE and safety measures needed to protect workers from arc flash hazards.

- Labeling and Documentation: Proper labeling of electrical equipment is essential for identifying arc flash risks. The audit ensures that all equipment is clearly labeled with arc flash hazard information, including incident energy levels and required PPE. Additionally, documentation of safety procedures and risk assessments is essential for maintaining compliance and ensuring that workers are aware of the hazards they may encounter.

- Review of Work Practices: The audit also evaluates work practices related to electrical safety. This includes reviewing lockout/tagout procedures, maintenance protocols, and employee training programs. By assessing these practices, the audit can identify areas where improvements are needed to reduce the risk of arc flash incidents.

What Steps Can Be Taken to Mitigate Arc Flash Risks?

Once arc flash risks have been identified through an electrical safety audit, organizations can take several steps to mitigate these risks and protect employees.

- Implementing Engineering Controls: Engineering controls are one of the most effective ways to reduce arc flash risks. These controls may include upgrading electrical equipment to reduce the likelihood of an arc flash, installing arc-resistant switchgear, and using current-limiting devices to minimize the energy released during an arc flash.

- Providing Appropriate PPE: Personal protective equipment (PPE) is essential for protecting workers from arc flash hazards. Based on the results of the arc flash risk assessment, organizations should provide employees with the appropriate PPE, such as flame-resistant clothing, insulated gloves, and face shields. Regular inspection and maintenance of PPE are also crucial to ensure its effectiveness.

- Establishing Safe Work Practices: Safe work practices are critical for minimizing arc flash risks. This includes implementing lockout/tagout procedures, ensuring proper grounding of equipment, and establishing clear guidelines for working near energized electrical equipment. Regular training and drills are essential for reinforcing these practices and ensuring that employees are prepared to respond to potential hazards.

- Conducting Regular Maintenance: Regular maintenance of electrical systems and equipment is essential for preventing arc flash incidents. This includes inspecting equipment for signs of wear or damage, testing protective devices, and performing routine cleaning and lubrication. By maintaining equipment in good condition, organizations can reduce the likelihood of arc flash incidents and ensure the safety of their employees.

- Promoting a Culture of Safety: Beyond implementing specific controls, fostering a culture of safety within the organization is essential for mitigating arc flash risks. This includes encouraging employees to report potential hazards, rewarding proactive safety behaviors, and promoting ongoing education and training on electrical safety.

How Can Organizations Address Compliance Issues Related to Electrical Safety?

Navigating compliance issues related to electrical safety can be challenging, especially given the complex and ever-changing nature of regulations. However, by taking a proactive approach, organizations can ensure that they meet all necessary requirements while also protecting their employees from electrical hazards.

- Staying Informed About Regulations: The first step in addressing compliance issues is staying informed about the specific regulations that apply to your industry and location. This includes national electrical codes, local regulations, and industry-specific standards. Regularly reviewing and updating your understanding of these regulations is essential for maintaining compliance.

- Conducting Compliance Audits: Regular compliance audits are essential for identifying any gaps or deficiencies in your electrical safety measures. These audits should be conducted by qualified professionals who are familiar with the specific regulations applicable to your organization. By addressing any non-compliance issues promptly, you can avoid potential penalties and ensure the safety of your facility.

- Documenting Safety Procedures: Proper documentation is essential for demonstrating compliance with electrical safety regulations. This includes maintaining records of safety inspections, risk assessments, training programs, and maintenance activities. Clear and accurate documentation helps ensure that your organization can provide evidence of compliance in the event of an inspection or audit.

- Engaging with Regulatory Authorities: Building positive relationships with regulatory authorities can be beneficial in addressing compliance issues. Engaging with electrical safety inspectors, code officials, and other relevant authorities can provide valuable insights into their expectations and requirements. This proactive approach can also help address any concerns or discrepancies before they become compliance issues.

- Leveraging Expert Support: Partnering with electrical safety experts, such as The Safety Master, can provide your organization with the expertise and guidance needed to navigate complex compliance requirements. Our team of experienced professionals can help you develop and implement comprehensive electrical safety strategies that go beyond compliance, ensuring the safety of your facility and employees.

Conclusion: Achieving Excellence in Electrical Safety with The Safety Master

At The Safety Master, we are committed to helping organizations achieve excellence in electrical safety. Our comprehensive electrical safety audits, arc flash risk assessments, and compliance support services are designed to protect your employees and ensure that your organization meets all necessary regulatory requirements.

By identifying and mitigating arc flash risks, implementing effective safety measures, and fostering a culture of safety, you can create a safer workplace for everyone. With The Safety Master by your side, you can be confident that your organization is well-prepared to handle electrical safety challenges and that your employees are equipped with the knowledge and tools needed to stay safe on the job.

In conclusion, electrical safety is a critical aspect of workplace safety, and arc flash risks should never be taken lightly. By conducting thorough electrical safety audits, addressing compliance issues, and implementing proactive safety measures, organizations can protect their employees and ensure long-term success.