Electrical Safety Audit – The Safety Master

Fire Audit- The Safety Master

March 28, 2024

HAZOP Safety Audit – The Safety Master

March 29, 2024Introduction

When it comes to workplace safety, especially in environments where electrical hazards are prevalent, conducting regular electrical safety audits is paramount. An electrical safety audit is a comprehensive assessment conducted to identify potential hazards, assess risks, and ensure compliance with safety regulations. In this article, we will delve into the critical aspects of arc flash risks in the workplace and how conducting an electrical safety audit can help mitigate these risks while addressing compliance issues.

Understanding Arc Flash Risks

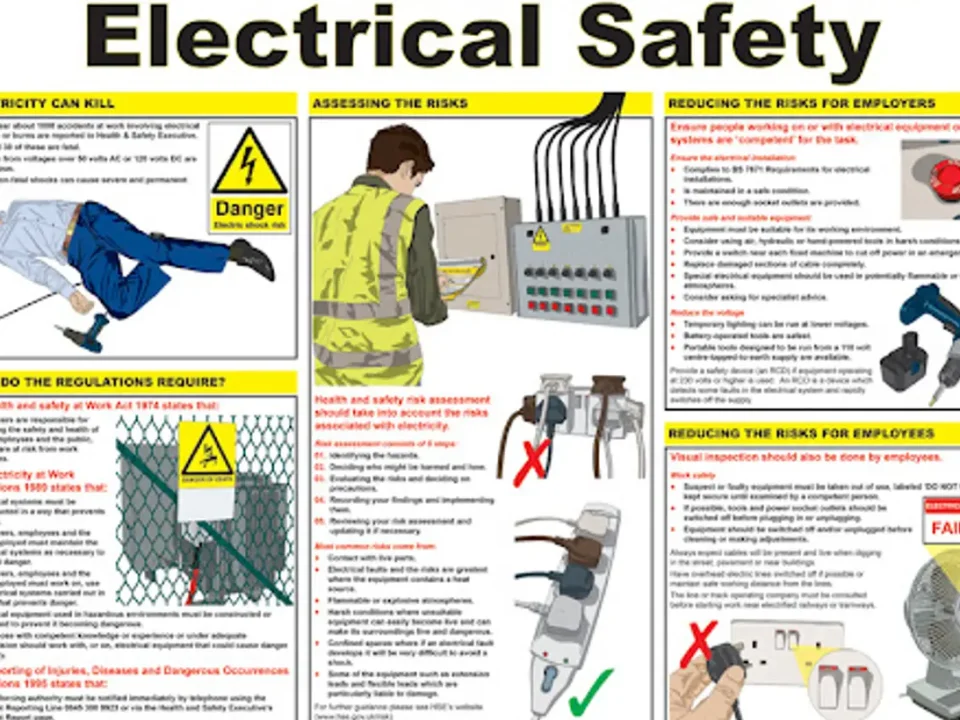

Arc flash is a sudden release of electrical energy due to a fault in an electrical system. This phenomenon can occur due to various factors such as equipment failure, improper maintenance, or human error. The intense heat and pressure generated during an arc flash can result in serious injuries, including burns, blindness, and even fatalities. Understanding the causes and potential consequences of arc flash incidents is essential for prioritizing safety measures in the workplace.

Conducting an Electrical Safety Audit

Before conducting an electrical safety audit, it is crucial to adequately prepare by gathering relevant documentation, such as electrical drawings, maintenance records, and incident reports. During the audit, trained professionals will assess the electrical infrastructure, identify potential hazards such as overloaded circuits or outdated equipment, and conduct a thorough risk assessment. Based on the findings, mitigation strategies will be developed to minimize the risk of arc flash incidents.

Addressing Compliance Issues

In addition to ensuring employee safety, electrical safety audits are also essential for maintaining compliance with regulatory standards and requirements. Regulatory bodies such as OSHA (Occupational Safety and Health Administration) have established guidelines to protect workers from electrical hazards. By conducting regular audits and addressing any compliance issues promptly, organizations can avoid costly fines and legal liabilities.

Implementing Safety Measures

Mitigating arc flash risks requires a multi-faceted approach that combines engineering controls, personal protective equipment (PPE), and employee training. Engineering controls such as arc-resistant switchgear and circuit breakers are designed to minimize the impact of arc flash incidents. Additionally, providing employees with proper PPE such as flame-resistant clothing and face shields can significantly reduce the risk of injuries. Comprehensive training programs should also be implemented to ensure that employees are aware of potential hazards and know how to respond in case of an emergency.

Case Studies and Real-Life Examples

To highlight the importance of electrical safety audits, we can look at real-life examples of organizations that have successfully implemented safety measures to prevent arc flash incidents. By learning from past incidents and implementing lessons learned, businesses can create safer work environments for their employees.

The Role of Technology in Electrical Safety

Advancements in technology have revolutionized the field of electrical safety, providing organizations with tools to assess risks more accurately and monitor electrical systems in real-time. From infrared thermography to predictive maintenance software, technology plays a crucial role in preventing arc flash accidents and ensuring the ongoing safety of employees.

Continuous Improvement and Monitoring

Electrical safety is not a one-time effort but rather an ongoing process that requires continuous evaluation and improvement. By regularly reviewing safety protocols, updating procedures based on new developments, and providing ongoing training to employees, organizations can create a culture of safety that prioritizes the well-being of everyone in the workplace.

Conclusion

In conclusion, conducting regular electrical safety audits is essential for identifying and mitigating arc flash risks in the workplace. By understanding the causes and potential consequences of arc flash incidents, implementing safety measures, and ensuring compliance with regulatory standards, organizations can create safer work environments for their employees. Through continuous improvement and monitoring, we can strive towards a future where arc flash accidents are minimized, and workplace safety is prioritized.