Emergency Response Plan Preparation for your Factory by TheSafetyMaster

HAZOP Leadership Training for 2 Days by TheSafetyMaster

August 8, 2023

Construction Safety Audit

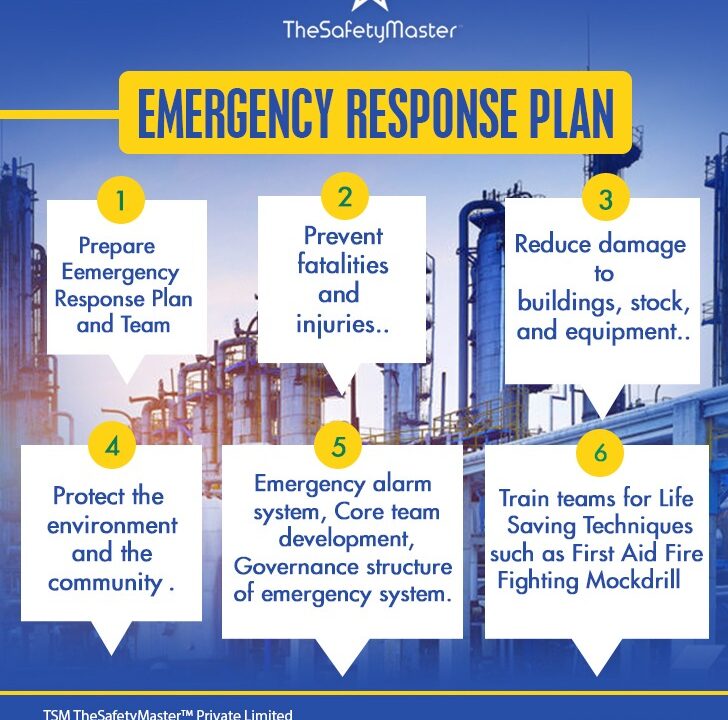

August 14, 2023Every factory, regardless of its size or industry, faces potential emergencies that can disrupt operations, jeopardize employee safety, and cause significant financial loss. The key to mitigating these risks lies in proper preparation and the development of an effective Emergency Response Plan. In this article, we delve into the crucial aspects of creating a comprehensive plan tailored specifically to your factory.

Throughout this article, TheSafetyMaster will guide you through the step-by-step process of preparing for emergencies in your factory. We will highlight potential risks that your facility might face and provide insights into assessing them effectively. Furthermore, we will discuss the creation of an Emergency Response Team comprising dedicated individuals trained to handle crisis situations swiftly and efficiently.

Understanding the Importance of Emergency Response Plans

When it comes to ensuring the safety and well-being of your employees and the smooth operation of your factory, having a well-prepared emergency response plan is absolutely crucial. It serves as a comprehensive roadmap that outlines the necessary steps to be taken in the event of any unforeseen disaster or emergency situation.

Without an effective emergency response plan in place, chaos could ensue, leading to potential injury, loss of life, and severe damage to property. By acknowledging and understanding the importance of such plans, you are taking proactive measures to protect your workforce and safeguard your assets.

The Story of a Factory That Ignored the Need for an Emergency Response Plan

Once upon a time, in a bustling industrial town, there stood a factory that prided itself on its efficiency and productivity. The workers toiled day and night, manufacturing goods that were in high demand across the nation. However, amidst all the success and prosperity, there was one critical aspect that the factory failed to prioritize – an emergency response plan.

Unbeknownst to the factory management, disaster can strike at any moment without warning. This unfortunate truth revealed itself one fateful day when a fire broke out in one of the production units. Panic ensued as alarms blared and smoke engulfed the building. The absence of an emergency response plan left employees confused and unprepared for such a dire situation.

In this moment of crisis, chaos reigned supreme. Workers scattered aimlessly, searching for exit routes or desperately attempting to extinguish the spreading flames with inadequate equipment. The lack of coordination led to delays in contacting the local fire department, exacerbating the already dire circumstances.

It was then that the gravity of their negligence struck hard upon the factory owners as they witnessed their beloved establishment succumbing to flames and crumbling under mounting pressure. Their failure to recognize the importance of an emergency response plan left them counting not only their financial losses but also mourning over preventable injuries suffered by their valued workforce.

This cautionary tale serves as a stark reminder that no matter how prosperous or successful we become, we must not overlook crucial aspects like preparedness for emergencies. By investing time and resources into developing a comprehensive emergency response plan tailored specifically for your factory’s needs, you can ensure swift

Assessing Potential Risks

Before implementing an effective emergency response plan, it is crucial to conduct a comprehensive assessment of potential risks specific to your factory. This step allows you to identify and evaluate the various hazards that could potentially jeopardize the safety of your employees and the overall operations of your facility.

To begin with, consider the nature of your industry and the type of machinery or equipment used in your factory. Are there any potential fire hazards, chemical spills, or electrical malfunctions that pose a threat? Furthermore, analyze the layout and structural integrity of your building. Are there any weak points or areas prone to collapse during emergencies?

It is equally important to assess external factors that may impact your factory’s safety. Take into account proximity to high-risk areas like factories handling hazardous materials, rivers or flood-prone regions, seismic zones, or areas vulnerable to natural disasters such as hurricanes or tornadoes. By thoroughly evaluating these risks both internal and external to your factory, you can develop strategies and protocols that will mitigate their effects.

Remember that risk assessment should be an ongoing process rather than a one-time event. Regular reviews and updates will allow you to stay ahead of emerging threats and adapt your emergency response plan accordingly. By taking a proactive approach towards assessing potential risks, you demonstrate commitment towards safeguarding lives and ensuring business continuity.

Creating the Emergency Response Team

Building a strong and efficient emergency response team is paramount to ensuring the safety and well-being of everyone in your factory. This team should consist of individuals who are knowledgeable, skilled, and reliable when it comes to handling emergency situations. Look for employees who possess leadership qualities, quick decision-making abilities, and are calm under pressure.

The first step in creating your emergency response team is to identify key personnel from different departments who will be responsible for coordinating and executing emergency procedures. These individuals should undergo specialized training that covers various aspects of emergency response, such as first aid, fire safety, hazardous material handling, and evacuation protocols.

An effective approach is to appoint a team leader who will oversee the entire emergency response process. This individual should have excellent communication skills to efficiently relay information between team members and other stakeholders during an emergency. By fostering a sense of camaraderie within the team and providing ongoing training opportunities, you can cultivate a culture that values safety above all else.

Remember that the strength of your emergency response team lies not only in their technical expertise but also in their ability to work together harmoniously. Encourage collaboration, teamwork, and regular practice drills to ensure seamless coordination when faced with unexpected events. By investing time and effort into creating a capable and cohesive emergency response team, you can feel confident that your factory is well-prepared for any crisis that may arise.

Developing Emergency Communication Channels

In times of crisis, effective communication is paramount. To ensure the safety and well-being of your factory’s employees, it is essential to establish robust emergency communication channels. This involves employing various methods to disseminate vital information quickly and efficiently.

One key aspect of developing emergency communication channels is implementing a multi-layered approach. This includes utilizing both traditional and modern means of communication to reach all individuals within your factory. Start by installing reliable public address systems throughout the premises, enabling clear and audible announcements in case of emergencies.

Designing Evacuation Routes and Assembly Points

When it comes to the safety of your employees during an emergency, having well-designed evacuation routes and strategically placed assembly points is crucial. These elements ensure a smooth and orderly evacuation process, minimizing panic and avoiding potential hazards.

The first step in designing evacuation routes is to thoroughly assess your factory layout. Identify all possible exits, taking into account both primary and secondary options. Consider factors such as the location of hazardous materials, machinery, or obstacles that might hinder safe passage. It is essential to create clear pathways that are easily accessible to everyone, including individuals with disabilities.

Next, clearly mark these routes with highly visible signs indicating the direction towards exits. Utilize luminous materials or reflective paint to enhance visibility during low-light situations. Additionally, consider using tactile indicators for visually impaired individuals. Regularly inspect and maintain these markings to ensure their effectiveness over time.

Assembly points should be strategically placed at safe distances from the building but still within close proximity for easy monitoring by emergency personnel. Ensure that assembly points have ample space for all employees to gather while maintaining proper physical distancing measures.

A thoughtful approach in designing evacuation routes and assembly points gives your employees a sense of security knowing that they have a designated path to follow during an emergency situation. By incorporating well-planned signage and maintaining these areas regularly, you demonstrate your commitment to their safety.

Stocking Emergency Supplies and Equipment

In times of crisis, having the necessary emergency supplies and equipment readily available can make a significant difference in the safety and well-being of your factory’s personnel. To ensure a swift response to any emergency situation, it is imperative to stock an array of essential items that cater to various types of emergencies.

Firstly, consider the basic provisions such as first aid kits containing bandages, antiseptic solutions, pain relievers, and other medical essentials. Additionally, ensure an ample supply of fire extinguishers strategically placed throughout the factory premises, taking into account different types of fires that might arise. It is also prudent to have a dedicated stockpile of emergency food and water rations to sustain individuals during prolonged situations.

To tackle unforeseen circumstances like power outages or communication failures, keep battery-powered radios or walkie-talkies with extra batteries on hand. These devices will not only facilitate effective coordination among the emergency response team but also provide vital updates about external developments affecting your factory’s operations.

To enhance preparedness for chemical spills or leaks, invest in spill containment kits tailored for your specific needs. These kits should include absorbent materials like pads and booms along with personal protective equipment (PPE) such as gloves and goggles. Additionally, place spill response stations equipped with neutralizing agents strategically at areas prone to chemical incidents.

Above all else, regularly review and replenish your stocked supplies to ensure their freshness and usability when emergencies arise. By taking these proactive measures in stocking necessary supplies and equipment, you instill confidence in your workforce while reinforcing a culture of preparedness that goes hand-in-hand with exceptional safety standards.</

Conducting Evacuation Drills and Training Sessions

Evacuation drills and training sessions are vital components of an effective emergency response plan. They provide employees with the necessary knowledge and skills to respond swiftly and safely in the face of a crisis. By conducting regular drills, your factory can ensure that everyone is well-prepared, confident, and capable of handling emergencies.

During evacuation drills, employees should be guided through different scenarios to simulate real-life emergency situations. This could include fires, chemical spills, or natural disasters. By replicating these scenarios, workers can practice executing designated evacuation routes, assembly points, and safety protocol. These drills also serve as an opportunity to identify any weaknesses in the response plan or areas where further training may be needed.

Training sessions should not only focus on physical actions but also on educating employees about potential risks they may encounter in the factory environment. They should receive guidance on recognizing warning signs of emergencies and how to report them promptly. Additionally, training sessions can address first aid techniques that may be required during critical moments.

Inspiring a sense of teamwork during these drills is crucial as it fosters a supportive atmosphere among colleagues when faced with adversity. Encourage employees to offer assistance to one another during simulated emergencies – this camaraderie can make all the difference when it comes to saving lives or preventing further harm.

Remember that through regular evacuation drills and comprehensive training sessions, your factory will cultivate a culture of preparedness where employees feel confident in their ability to handle any unexpected situation that may arise. When every member of your team is well-equipped with knowledge and skills for emergency response, you can rest assured that both your

Maintaining and Updating the Emergency Response Plan

Creating an effective emergency response plan is a significant achievement, but it doesn’t end there. In order to ensure its ongoing relevance and effectiveness, regular maintenance and updates are essential. Think of your emergency response plan as a living document that needs nurturing and attention to keep it robust and adaptable to changing circumstances.

Regularly review your plan to identify any gaps or areas that require improvement. Consider incorporating feedback from employees who have participated in drills or training sessions, as they often offer valuable insights. Stay up-to-date with current best practices in emergency management by attending workshops or conferences, and consult with experts in the field to ensure that your plan aligns with industry standards.

Conclusion

In conclusion, it is evident that the preparation of an effective Emergency Response Plan is a critical aspect of ensuring the safety and well-being of employees in any factory setting. By diligently assessing potential risks, creating a dedicated emergency response team, establishing robust communication channels, designing efficient evacuation routes, stocking necessary supplies and equipment, conducting regular drills and training sessions, as well as maintaining and updating the plan as needed, factories can significantly enhance their ability to respond swiftly and effectively in times of crisis. Remember, every step taken towards preparedness brings us closer to a safer work environment where peace of mind prevails. As Benjamin Franklin once said, “By failing to prepare, you are preparing to fail.”

Sanjeev Paruthi

TSM TheSafetyMaster® Private Limited

Unit No 221-451-452, SPL1/J, 2nd & 4th Floor, Sunsquare Plaza Complex, RIICO Chowk, Bhiwadi 301019, Rajasthan, India

Phone: +91 1493 22 0093

Mobile: +91 7665231743/9413882016

Email: info@thesafetymaster.com