Ergonomics Audit and Heat Stress Calculation by TheSafetyMaster

Industrial Hygiene Assessment and Environment Monitoring services by TheSafetyMaster

August 19, 2023

Behavior Based Safety vs. Traditional Safety Approaches: Which One Works Best?

August 22, 2023Imagine a workplace where employees feel comfortable, productive, and safe. A place where the risk of injuries and heat-related illnesses is minimized, leading to happier and more motivated workers. This is the vision that TheSafetyMaster aims to help organizations achieve through their expertise in ergonomics audit and heat stress calculation.

In this article, we will delve into the world of ergonomics audit and heat stress calculation, exploring how these essential practices can transform your workplace. We will guide you through the step-by-step process of conducting an ergonomics audit, highlight the importance of assessing potential heat stress risks, and provide insights into calculating the heat stress index.

By following TheSafetyMaster’s comprehensive approach to ergonomics audit and heat stress calculation, you will not only ensure the well-being of your employees but also optimize their performance. So get ready to learn valuable techniques that will make your workplace a haven of comfort and productivity!

The Importance of Ergonomics in the Workplace

In today’s fast-paced and highly competitive world, organizations strive to create a productive and efficient work environment. An often overlooked aspect of achieving this goal is the implementation of proper ergonomics in the workplace. Ergonomics, the study of designing tasks, equipment, and workspaces to fit the capabilities and limitations of individuals, plays a vital role in enhancing employee well-being and overall organizational success.

By prioritizing ergonomics, companies demonstrate their commitment to employee health and safety. A well-designed ergonomic workspace not only minimizes the risk of injuries but also optimizes employee performance by reducing physical strain, fatigue, and discomfort. When employees are comfortable and supported in their work environment, they are more likely to be motivated, focused, and productive. This leads to improved job satisfaction levels among workers while simultaneously reducing absenteeism rates.

Understanding the Concept of an Ergonomics Audit

An ergonomics audit is a systematic assessment of the various elements within a workplace that affect the comfort, health, and productivity of employees. It involves evaluating how well the work environment and job tasks align with the capabilities and limitations of workers. The ultimate goal is to identify potential areas for improvement and implement appropriate ergonomic solutions.

By conducting an ergonomics audit, organizations can ensure that their workspaces are designed in a way that minimizes the risk of musculoskeletal disorders, reduces fatigue and discomfort, and enhances overall job performance. This holistic approach acknowledges that every individual is unique, with different physical abilities and limitations. It recognizes the importance of creating a workspace where employees can thrive.

Step-by-Step Guide to Conducting an Ergonomics Audit

In order to ensure a safe and healthy work environment for your employees, conducting an ergonomics audit is essential. The process can be broken down into several key steps that will allow you to identify potential hazards, assess risk levels, and implement effective control measures. Let’s delve into each step:

1. Preliminary Research: Begin by familiarizing yourself with the tasks performed in each job position. This will help you understand the specific ergonomic requirements and potential risks associated with each task.

2. Walkthrough Assessment: Conduct a thorough walkthrough of the workplace, observing employees as they perform their tasks. Look for any signs of discomfort or strain, note any awkward postures or repetitive motions, and identify any poorly designed workstations or equipment.

3. Employee Interviews: Engage in open conversations with employees to gain insights into their experiences and any discomfort they may be facing while performing their duties. Encourage them to share their concerns and suggestions for improvement.

4. Documentation: Accurately record your findings during the walkthrough assessment and employee interviews. Include detailed notes about specific issues observed, as well as photographs or videos that can serve as visual evidence.

5. Analysis: Review all collected data from your research, walkthrough assessment, and employee interviews. Identify common ergonomic issues across different job positions and prioritize them based on severity.

6. Action Plan Development: Develop a comprehensive action plan that addresses the identified ergonomic issues systematically. This may involve rearranging workstations, providing adjustable furniture or tools, introducing proper training programs, or implementing other control measures.</

Assessing Potential Heat Stress Risks in the Workplace

When it comes to ensuring the well-being of employees, assessing potential heat stress risks in the workplace is of paramount importance. Heat stress can result from a combination of high temperatures, humidity, and physical exertion, posing serious threats to workers’ health and productivity. Identifying areas where heat stress may occur allows proactive measures to be taken, fostering a safe and comfortable work environment.

During the assessment process, it is crucial to consider various factors that contribute to heat stress risks. These include ambient temperature, air movement, radiant heat sources, clothing worn by employees, duration of exposure to high temperatures, and individuals’ physical activity levels. By thoroughly evaluating these variables in different work areas and job tasks within an organization, potential hotspots can be identified.

The assessment should involve close collaboration between management and employees. Conducting interviews or surveys with individuals working in diverse roles helps gather valuable insights about their experiences with heat-related discomfort or symptoms. Additionally, monitoring environmental conditions through advanced technological tools like temperature sensors or thermal imaging cameras aids in obtaining accurate data for analysis.

Ultimately, by diligently assessing potential heat stress risks within the workplace environment and engaging employees in this process, organizations demonstrate their commitment to prioritizing employee safety. This approach fosters a positive work culture while enabling proactive measures to be implemented effectively.

Calculating Heat Stress Index to Ensure Employee Safety

When it comes to maintaining a safe and comfortable work environment, understanding and managing heat stress is paramount. Heat stress can have serious consequences on employee well-being and productivity, making it essential to accurately calculate the heat stress index. This index allows us to assess the level of thermal discomfort an individual may experience due to environmental conditions, enabling us to implement appropriate control measures.

The calculation of the heat stress index involves considering various factors such as air temperature, humidity, air velocity, radiant heat sources, and personal protective equipment. By quantifying these elements accurately, we gain valuable insights into the level of thermal strain employees are exposed to during their duties. Armed with this knowledge, we can develop effective strategies for preventing and managing heat-related illnesses.

Tools and Techniques for Heat Stress Calculation

Accurate heat stress calculation is crucial for identifying potential risks and implementing effective control measures in the workplace. Fortunately, there are several reliable tools and techniques available to ensure precision and reliability in this process.

One commonly used tool is the Wet Bulb Globe Temperature (WBGT) index. This index takes into account various factors such as air temperature, humidity, wind speed, and radiant heat to provide a comprehensive assessment of heat stress levels. By measuring these parameters with specialized devices like globe thermometers, wet bulb thermometers, and anemometers, employers can obtain accurate WBGT readings that enable them to make informed decisions about necessary interventions.

In addition to the WBGT index, technological advancements have brought about the use of portable heat stress monitors. These handheld devices can measure environmental factors such as temperature, humidity, solar radiation, and air velocity in real-time. With their user-friendly interfaces and instant feedback capabilities, these monitors offer convenience while ensuring accurate assessments of heat stress levels.

By utilizing these advanced tools along with comprehensive data collection techniques like time-weighted average (TWA) sampling methods over multiple work shifts or using personal monitors worn by employees during their tasks, companies can gain valuable insights into the specific areas or job roles with high risk of heat stress. Armed with this knowledge, they can take proactive steps to amend work schedules or introduce engineering controls (such as increased ventilation or insulation) to mitigate potential hazards effectively.

Interpreting the Results of Your Heat Stress Calculation

Once you have conducted a thorough heat stress calculation using reliable tools and techniques, it is essential to interpret the results accurately. Understanding the implications of the data will enable you to implement effective control measures to ensure employee safety and well-being.

When interpreting heat stress calculation results, it is crucial to pay attention to various factors. These include the Wet Bulb Globe Temperature (WBGT), which measures heat stress based on air temperature, humidity, wind speed, and radiant heat. The American Conference of Governmental Industrial Hygienists (ACGIH) provides guidelines for interpreting WBGT values.

Additionally, consider assessing the metabolic rate of workers involved in different tasks as it affects their heat production. Identification of personnel who may be more susceptible to heat stress due to individual characteristics such as age or medical conditions is also important. By taking all these factors into account, you can determine whether your workplace is within acceptable limits or requires further action.

Incorporating an optimistic spin, understanding how to interpret heat stress calculations empowers organizations to proactively address potential risks and prioritize employee well-being. By accurately identifying areas that require attention and implementing appropriate control measures, companies can create a safe working environment that promotes productivity and fosters a positive company culture.

Implementing Effective Control Measures to Mitigate Heat Stress

When it comes to safeguarding the well-being of your employees, implementing effective control measures is paramount in mitigating the risks associated with heat stress. By taking proactive steps to address this issue, not only can you ensure a safe and comfortable working environment, but you can also foster a sense of trust and loyalty among your workforce.

One of the first control measures to consider is modifying work schedules to avoid prolonged exposure to extreme heat. This could involve adjusting shift timings or allowing for frequent breaks in temperature-controlled areas. Additionally, providing employees with appropriate personal protective equipment, such as cooling vests or reflective clothing, can significantly reduce the impact of heat stress. The installation of proper ventilation systems and air conditioning units should also be considered to regulate indoor temperatures effectively.

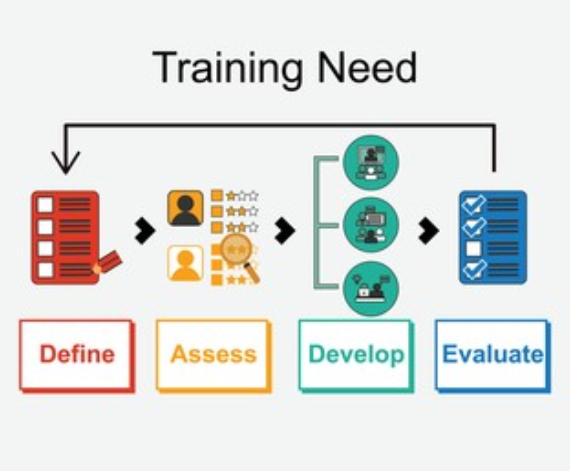

Training and Education for Employees on Heat Stress Prevention

Ensuring the safety and well-being of employees should always be a top priority for any organization. When it comes to heat stress prevention, it is imperative to provide comprehensive training and education to all employees. By equipping them with the necessary knowledge and understanding of heat stress risks, they can actively contribute to creating a safe working environment.

In the training sessions, employees will learn about the various factors that contribute to heat stress, including high temperatures, humidity levels, physical exertion, and personal factors such as clothing choices. They will gain insights into recognizing early symptoms of heat stress in themselves and their colleagues. Through interactive workshops and engaging presentations, they will understand the importance of hydration and proper rest breaks in preventing heat-related illnesses.

Furthermore, the training will cover strategies to mitigate heat stress risks effectively. Employees will learn about using cooling measures such as fans or personal cooling devices. They will also be educated on adjusting work schedules to minimize exposure during peak temperature hours. In addition, proper clothing selection suitable for hot environments will be discussed.

The goal of this training is not only to inform but also empower employees to become proactive in managing their own safety when it comes to heat stress prevention. By fostering a culture of awareness and responsibility within the workforce, organizations can create an environment where every individual becomes a guardian of their own well-being as well as that of their colleagues.

Real-Life Case Study: How an Ergonomics Audit and Heat Stress Calculation Transformed Company XYZ

Imagine a workplace plagued by high rates of absenteeism, reduced productivity, and a demoralized workforce. This was the unfortunate reality for Company XYZ, a bustling manufacturing firm facing the challenges of poor ergonomics and heat stress. However, with an astute understanding of the importance of employee well-being, the management decided to conduct an in-depth ergonomics audit and implement a heat stress calculation to address these issues head-on.

The results were nothing short of remarkable. Armed with insights gained from the ergonomics audit, Company XYZ made significant changes to their workstations and equipment layout, optimizing them for improved posture and reducing muscle strain. Additionally, by utilizing advanced heat stress calculation methods tailored to their specific environment, they were able to identify areas where temperature control measures needed improvement.

Conclusion

In conclusion, conducting an ergonomics audit and implementing heat stress calculation measures are crucial steps in ensuring the well-being, productivity, and safety of employees in any workplace. By being proactive in identifying potential risks and taking appropriate actions to mitigate them, companies can create a conducive environment that fosters employee satisfaction and reduces the likelihood of accidents or health issues. Remember, investing in the health and comfort of your workforce is not only a legal obligation but also a smart business decision that leads to higher employee morale, increased productivity, and ultimately, greater success for your organization. So let us embrace the power of ergonomics and prioritize the well-being of our workforce – because when they thrive, so does our business.

Sanjeev Paruthi

TSM TheSafetyMaster® Private Limited

Unit No 221-451-452, SPL1/J, 2nd & 4th Floor, Sunsquare Plaza Complex, RIICO Chowk, Bhiwadi 301019, Rajasthan, India

Phone: +91 1493 22 0093

Mobile: +91 7665231743/9413882016

Email: info@thesafetymaster.com