Exothermic Reaction Hazards

Material Handling Audit Including crane, Forklift, Hydra

October 29, 2024

Hazardous Chemical Safety Training on Chemical & Hazard Identification Risk Assessment

November 7, 2024Exothermic reactions are chemical reactions that release heat as they occur. While these reactions are fundamental in various industrial processes, they pose significant hazards if not properly managed. Understanding and mitigating these hazards is crucial to ensuring the safety of personnel, equipment, and the environment. This article delves into the nature of exothermic reaction hazards, their potential consequences, and the strategies to manage these risks effectively.

Understanding Exothermic Reactions

In an exothermic reaction, the energy released as heat is a product of the reaction. Common examples include combustion, oxidation, and certain polymerization processes. These reactions are characterized by an increase in temperature, which can sometimes lead to uncontrollable conditions if the heat is not properly dissipated.

Potential Hazards of Exothermic Reactions

- Thermal Runaway: One of the most significant risks associated with exothermic reactions is thermal runaway. This occurs when the heat generated by the reaction accelerates the reaction rate, causing an exponential increase in temperature. If not controlled, thermal runaway can lead to explosions, fires, and catastrophic equipment failure.

- Pressure Build-Up: Exothermic reactions can generate gases, leading to an increase in pressure within the reaction vessel. If the pressure exceeds the design limits of the containment system, it can result in vessel rupture and release of hazardous materials.

- Fire and Explosion: The heat and gases produced by exothermic reactions can ignite flammable substances, causing fires and explosions. This is particularly dangerous in environments where volatile chemicals are present.

- Release of Toxic Substances: Some exothermic reactions can produce toxic by-products. In the event of an uncontrolled reaction, these substances can be released into the environment, posing health risks to workers and surrounding communities.

Case Studies Highlighting Exothermic Reaction Hazards

- T2 Laboratories Explosion (2007): A tragic example of thermal runaway occurred at T2 Laboratories in Jacksonville, Florida. During the production of a gasoline additive, an exothermic reaction went out of control, leading to an explosion that killed four workers and injured many others. The incident underscored the importance of proper reaction monitoring and emergency relief systems.

- West Pharmaceutical Services Explosion (2003): A dust explosion caused by an exothermic reaction resulted in the deaths of six workers and the destruction of the facility. This incident highlighted the dangers of flammable dusts and the need for stringent safety measures in handling reactive materials.

Managing Exothermic Reaction Hazards

- Process Safety Management: Implementing a robust Process Safety Management (PSM) system is essential. PSM involves a systematic approach to identifying, evaluating, and controlling hazards associated with chemical processes. This includes conducting thorough hazard analyses, maintaining accurate process documentation, and ensuring that safety systems are in place and functional.

- Process Safety Training: Educating workers on the specific hazards of exothermic reactions and the proper handling of reactive chemicals is crucial. Regular process safety training ensures that personnel are aware of potential risks and the steps needed to mitigate them.

- Temperature and Pressure Control: Monitoring and controlling temperature and pressure within reaction vessels is vital. Automated systems can provide real-time data and trigger safety mechanisms if predefined limits are exceeded. This helps prevent thermal runaway and pressure build-up.

- Cooling Systems: Effective cooling systems are essential to dissipate the heat generated during exothermic reactions. These systems should be designed to handle the maximum heat output and include redundancy to ensure continued operation in case of component failure.

- Emergency Relief Systems: Installing pressure relief devices, such as safety valves and rupture discs, can prevent catastrophic vessel failure by allowing controlled release of pressure. These systems should be regularly inspected and maintained to ensure their reliability.

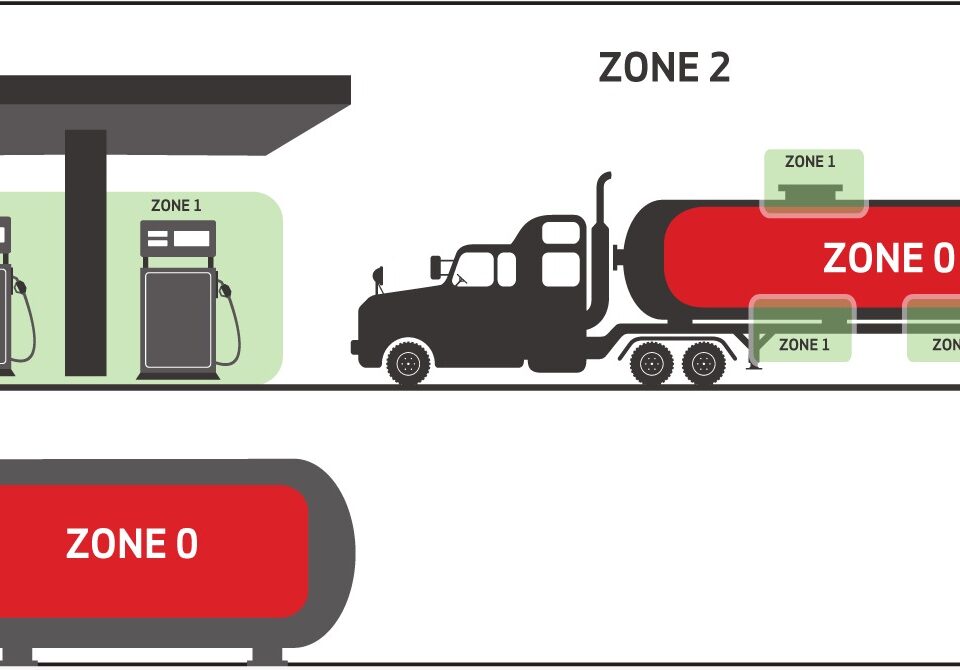

- Fire Risk Assessment: Conducting a comprehensive fire risk assessment is crucial in identifying potential ignition sources and implementing measures to prevent fires and explosions. This includes controlling static electricity, proper storage of flammable materials, and ensuring that fire suppression systems are in place and functional.

- Arc Flash Assessment: An arc flash assessment is necessary in facilities where electrical equipment is used in conjunction with chemical processes. This assessment helps identify potential electrical hazards and implement protective measures to prevent arc flash incidents, which can ignite exothermic reactions.

- Regular Safety Audits: Regular safety audits, including electrical safety audits, ensure that all safety systems and procedures function correctly. These audits help identify potential weaknesses and areas for improvement in managing exothermic reaction hazards.

Conclusion

Exothermic reactions are a double-edged sword in industrial processes, offering both benefits and significant hazards. The key to harnessing their potential while minimizing risks lies in understanding the nature of these reactions and implementing comprehensive safety measures. By adopting robust process safety management systems, providing thorough process safety training, and conducting regular safety assessments, organizations can effectively manage the hazards associated with exothermic reactions. This proactive approach not only protects lives and property but also ensures the continuity and efficiency of industrial operations.