Hazardous area classification standards for flammable substances

Electrical safety regulations in India

October 5, 2023

Protecting Lives and Assets: How Electrical Safety Training Saves Businesses from Disasters

October 5, 2023Imagine a world where our surroundings teem with hidden dangers, lurking in every nook and cranny. Picture a scenario where flammable substances, capable of causing catastrophic fires and explosions, exist within our daily environments. This grim reality underscores the critical need for understanding hazardous area classification standards for flammable substances.

In this comprehensive article, we delve deep into the realm of hazardous area classification to shed light on the intricacies of identifying and mitigating potential risks. By exploring various flammable substances and their properties, uncovering the standards that govern hazard classification, and outlining practical steps for conducting risk assessments, we equip you with valuable knowledge to navigate these perilous realms safely. So buckle up as we embark on a journey through safety protocols that promise peace of mind amidst potentially explosive situations.

Understanding the Importance of Hazardous Area Classification

In the realm of industrial safety, understanding the importance of hazardous area classification is paramount. It serves as a fundamental pillar in safeguarding lives, protecting assets, and ensuring the smooth functioning of various industries. The consequences of neglecting proper classification can be dire, leading to catastrophic accidents and irreparable damage.

Imagine a world without hazardous area classification—where flammable substances are handled without precautionary measures in place. Chaos would reign supreme, with potential ignition sources lurking amidst volatile environments. The absence of clear guidelines and standards would render safety protocols obsolete. Thankfully, through meticulous analysis and categorization, we have been able to gain invaluable insights into minimizing risks associated with flammable substances.

The Story of a Life-Changing Incident

Once upon a time, in a bustling industrial facility, there existed an atmosphere teeming with unspoken dangers. The workers toiled tirelessly, unaware of the imminent catastrophe that loomed overhead. It was just another routine day until fate intervened and forever altered their lives.

Amidst the hum and whir of machinery, an unnoticed spark ignited a dormant cloud of flammable vapor. Within seconds, chaos reigned as flames erupted with an unforgiving fury. Panic gripped the employees as they scrambled for safety, their lives hanging precariously in the balance.

However, this tale takes a remarkable turn. As serendipity would have it, this industrial haven had embraced stringent hazardous area classification standards before disaster struck. Emergency systems sprang into action as if guided by divine intervention, extinguishing the inferno swiftly and efficiently.

In the aftermath of this life-changing incident, a renewed sense of appreciation for thorough hazard assessment and precautionary measures took hold within those walls. The employees rallied together to create a culture steeped in safety consciousness—a testament to the resilience of human spirit when faced with adversity.

What Are Flammable Substances and Why Are They Dangerous?

Flammable substances, often referred to as flammable materials or flammables, are those that have the potential to catch fire easily when exposed to various ignition sources. These substances encompass a broad range of chemicals, gases, liquids, and solids that possess certain properties that make them highly combustible. The danger they pose lies in their ability to rapidly release energy in the form of heat and flame, leading to potentially devastating fires or explosions.

The intrinsic hazardous nature of flammable substances arises from their capacity to mix with air or oxidizing agents in such a way that they can sustain combustion. Whether it is gasoline, solvents used in industrial processes, liquefied petroleum gas (LPG), or even common household items like aerosol sprays and lighter fluids—all these materials share the propensity for ignition when exposed to an ignition source such as open flames, sparks, electrical arcs, or even hot surfaces.

Understanding why flammable substances are dangerous is crucial for ensuring safety in various industries where these materials are handled or stored. Without proper precautions and controls in place, accidents involving these substances can lead to severe injuries, property damage on a large scale, or even loss of life. Nonetheless, it is important not only to focus on the hazards but also to recognize the potential for safe handling and prevention through robust risk assessment techniques and adherence to rigorous safety standards.

Exploring Various Flammable Substances and Their Properties

Flammable substances are like enigmatic entities that possess a captivating combination of potential danger and utility. From the volatile nature of gasoline to the mystical properties of hydrogen, each substance holds its own unique allure. Understanding their properties is crucial for effective hazardous area classification and risk management.

Take gasoline, for instance – an elixir powering our vehicles with its combustible charisma. This liquid hydrocarbon compound boasts a low flash point, making it highly susceptible to ignition even at room temperature. Its volatility is further accentuated by its vapor pressure, which allows it to readily transition from liquid to gaseous state, filling the air with flammable potential.

In contrast, hydrogen presents itself as an ethereal element with tremendous energy potential. Its buoyant nature and wide-ranging applications in various industries make it an intriguing subject for study. However, this colorless gas can be highly reactive and pose explosion risks in certain concentrations when combined with oxygen or other oxidizing agents.

By deepening our knowledge of these flammable substances’ properties, we empower ourselves to navigate their inherent dangers while harnessing their transformative qualities safely. Remembering that within the realm of danger often lies opportunity allows us to approach these substances not merely as threats but also as gateways toward innovation and progress.

Unveiling Hazardous Area Classification Standards

When it comes to the safe management of flammable substances, understanding and implementing hazardous area classification standards is of paramount importance. These standards serve as a crucial framework for identifying and categorizing areas where flammable gases, vapors, or dusts may be present in quantities that could potentially ignite or explode under specific conditions.

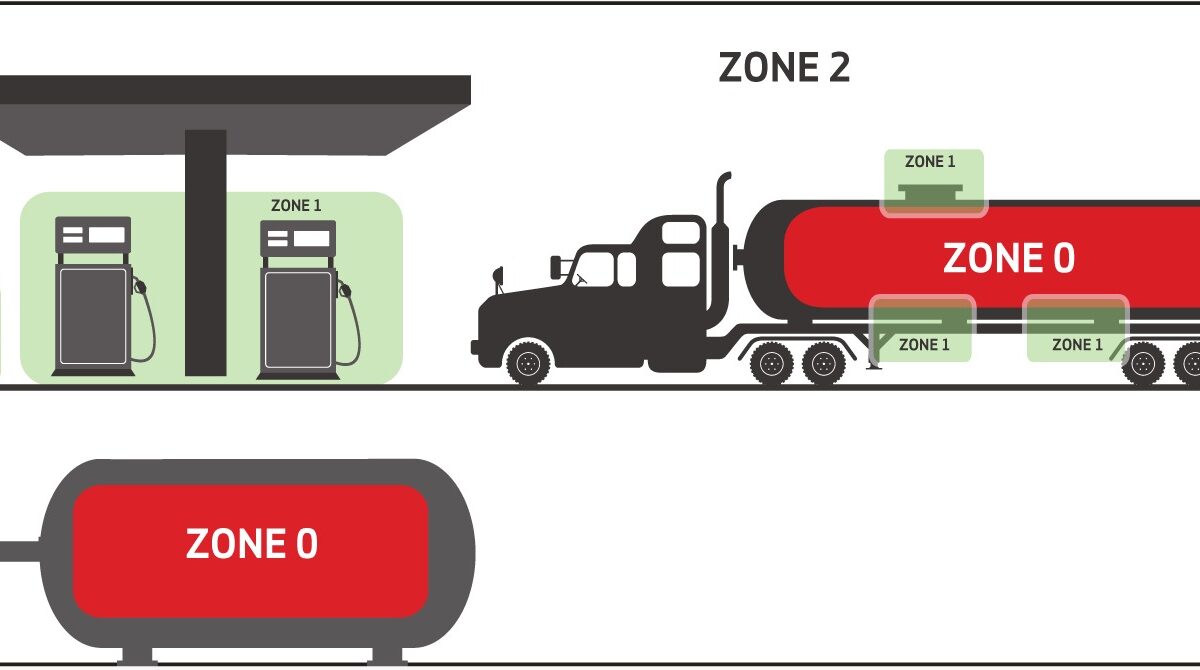

One widely recognized set of classification standards is the National Electrical Code (NEC) in the United States, which provides guidelines for classifying hazardous areas based on the nature of the flammable substances present. The NEC categorizes hazardous areas into different classes, divisions, and zones to ensure appropriate safety measures are in place. By carefully assessing factors such as substance characteristics, concentration levels, ignition sources, ventilation systems, and other variables, organizations can determine the most effective methods for preventing accidents and protecting lives.

How to Conduct a Comprehensive Risk Assessment

Conducting a comprehensive risk assessment is the cornerstone of ensuring safety in hazardous areas. It involves a meticulous examination and evaluation of potential risks associated with flammable substances. By following a systematic approach, organizations can identify, analyze, and prioritize risks to effectively implement preventive measures.

The first step in conducting a risk assessment is gathering relevant data about the hazardous area. This includes information about the flammable substances present, their properties, quantities stored or used, as well as any existing containment systems or safety measures. Additionally, it is crucial to consider external factors such as environmental conditions and proximity to ignition sources.

Once the necessary data has been collected, the next step is identifying potential hazards and assessing their likelihood and consequence. This involves analyzing various scenarios that could lead to an incident or escalation of risks. By considering factors such as ignition sources, ventilation systems, and process operational conditions, organizations can gain insights into how these hazards may interact and impact the overall safety of the area.

A comprehensive risk assessment also entails quantifying risks based on their severity and probability. This allows organizations to prioritize mitigation efforts by focusing on high-risk areas first. Various techniques are employed for risk quantification including semi-quantitative methods such as Risk Matrix or Quantitative Risk Analysis using mathematical models.

Finally, after identifying and quantifying risks, it is essential to develop control measures that effectively mitigate these risks. These control measures can include engineering controls (e.g., ventilation systems), administrative controls (e.g., standard operating procedures), and personal protective equipment (PPE). It is crucial for organizations to invest in regular reviews of these control measures to ensure

Step-by-Step Guide to Classifying Hazardous Areas

Classifying hazardous areas is a meticulous process that requires careful analysis and adherence to established standards. By following a step-by-step guide, organizations can ensure the safety of their personnel and mitigate potential risks associated with flammable substances.

The first crucial step is to gather comprehensive information about the site and its operations. This includes identifying all potential sources of flammable substances, such as storage tanks, pipelines, or process equipment. Additionally, it is essential to gather data on the quantities and characteristics of these substances.

Next, the collected data should be analyzed to determine the likelihood of an accidental release and assess its potential consequences. This involves considering factors such as temperature, pressure, ventilation systems, ignition sources, and any other relevant conditions that could contribute to a hazardous environment.

Once the risk assessment is complete, it’s time to establish the boundaries of each hazardous area based on criteria defined by industry regulations. This involves applying zone classification principles or division standards depending on the region-specific guidelines.

The next step requires marking these boundaries clearly with appropriate signage and labels. Effective communication through clear visual cues ensures that all personnel are aware of entering potentially dangerous areas.

To maintain safety standards in classified zones over time, regular inspections and audits are necessary. These assessments should identify changes in processes or equipment that may impact hazard levels or require modifications in classification boundaries.

Lastly, it is essential to remember that classifying hazardous areas is not a one-time endeavor but an ongoing process requiring continuous monitoring and evaluation. By staying vigilant amidst evolving workplace conditions and implementing necessary updates promptly, organizations can foster a culture of

The Role of Ventilation and Electrical Equipment in Hazardous Areas

Ventilation plays a pivotal role in maintaining safe conditions within hazardous areas. Proper ventilation systems are designed to dissipate flammable vapors, gases, or dusts that may accumulate in these areas. These systems utilize a combination of mechanical extractors, fans, and ducts to ensure a constant flow of fresh air. By removing the potentially combustible substances from the environment, ventilation greatly reduces the risk of ignition and subsequent catastrophic incidents.

Electrical equipment also plays a crucial part in hazardous area classification. In these environments, it is essential to use equipment specifically designed for use in potentially explosive atmospheres. Electrical apparatus can be equipped with explosion-proof enclosures that prevent sparks or arcs from igniting nearby flammable substances. Additionally, equipment should be regularly inspected and maintained to ensure its integrity and continued safe operation.

Adequate ventilation systems and properly certified electrical equipment not only mitigate risks but also instill confidence among workers operating within hazardous areas. The knowledge that their workspace is equipped with effective measures enhances their sense of security and fosters an environment conducive to productivity.

Implementing Necessary Safety Measures for Flammable Substances

When it comes to handling flammable substances, ensuring the utmost safety is not merely an option, but an obligation. Implementing effective safety measures is paramount to safeguarding lives and protecting valuable assets. The key lies in a comprehensive risk management approach that includes preventive strategies, state-of-the-art equipment, and a well-trained workforce.

One essential safety measure is the proper storage and handling of flammable substances. This involves utilizing designated containers that are specifically designed to withstand the hazards associated with these materials. Implementing secure storage facilities, such as specially constructed cabinets or rooms with fire-resistant features, ensures that potential risks are minimized and contained.

Training and Education for Safe Handling and Prevention

When it comes to dealing with flammable substances in hazardous areas, knowledge is power. Proper training and education are crucial in ensuring the safe handling and prevention of incidents. By equipping individuals with the necessary skills and understanding, we empower them to make informed decisions that can save lives.

A comprehensive training program should cover a wide range of topics, including hazard identification, risk assessment, emergency response protocols, and proper use of personal protective equipment (PPE). It should emphasize the importance of following established safety procedures to mitigate potential dangers.

Moreover, training sessions should be dynamic and engaging, incorporating real-life case studies that highlight success stories where individuals have effectively prevented accidents through their knowledge and quick thinking. By showcasing these examples, trainees are inspired to embrace a proactive safety mindset as they witness the positive impact they can make by adhering to proper procedures.

Inspiring Success Stories of Safe Practices in Hazardous Environments

Within the realm of hazardous environments, there exist remarkable tales of individuals and organizations embracing safety measures with unwavering dedication. These inspiring success stories not only demonstrate the potential for mitigating risks associated with flammable substances but also highlight the profound impact such practices have on both personal well-being and industrial operations.

One such story revolves around a chemical plant in a bustling urban area that experienced a potentially catastrophic incident. However, due to meticulous adherence to proper hazardous area classification standards and comprehensive risk assessments, disaster was averted. The plant’s management had invested significantly in state-of-the-art safety equipment, trained their staff meticulously, and fostered a culture that prioritized safety above all else.

Conclusion

In conclusion, the hazardous area classification standards for flammable substances play a crucial role in ensuring the safety of personnel and preventing catastrophic incidents. By understanding the properties of various flammable substances and conducting comprehensive risk assessments, industries can implement necessary safety measures to mitigate hazards effectively. Through proper training and education, individuals can acquire the knowledge and skills needed to handle these substances safely. While the risks associated with flammable substances cannot be completely eliminated, the success stories of organizations that have implemented these standards provide hope and inspiration for a safer future. Let us continue to strive for excellence in upholding these standards, committing ourselves to protecting lives and environments from potential harm.