Hydrogen Safety

The Role Of Workplace Safety Consultants In Building A Safety Culture in the Industry

May 9, 2023

The Importance of Workplace Safety Consultants and Fire Audits: The Safety Master as the Best Safety Consultant

May 10, 2023Understanding Hydrogen Safety

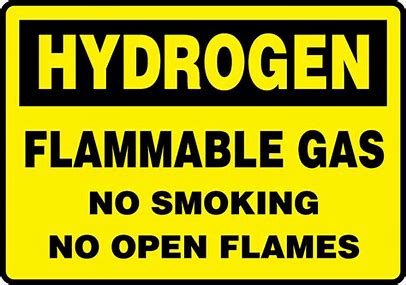

Hydrogen is a versatile fuel with a wide range of applications in industries such as transportation, energy production, and manufacturing. However, it is important to handle and store hydrogen with the utmost care due to its highly flammable nature. Understanding hydrogen safety is crucial for preventing accidents and ensuring the safe use of this valuable resource.

Hydrogen behaves differently than other gases due to its low density and high flammability. It can easily ignite when exposed to heat or an ignition source such as a spark or flame. Additionally, hydrogen flames are invisible, making it difficult to detect potential hazards. Therefore, it is essential to take extra precautions when handling hydrogen.

In order to ensure hydrogen safety, it is necessary for individuals working with the gas to be well-versed in its properties and behavior. Proper training should cover topics such as safe handling procedures, monitoring techniques, and emergency protocols. It is also essential that all equipment used for storing and distributing hydrogen be designed specifically for this purpose and regularly inspected for wear or damage.

How Hydrogen Behaves in Different Situations

Hydrogen is a unique gas that behaves differently than other common gases, such as oxygen or nitrogen. One of the most important things to understand about hydrogen is its high flammability. When released into the air, hydrogen can ignite and quickly burn at low concentrations. This means that even small leaks or spills of hydrogen gas can lead to dangerous situations.

Another important factor to consider in hydrogen behavior is its low density. Due to this property, hydrogen can easily escape from containers or pipes and mix with air, creating a potentially explosive mixture. Additionally, because hydrogen is odorless and colorless, it can be difficult to detect when it is leaking.

To ensure safe handling of hydrogen in different situations, it’s critical to understand the behavior of the gas and how it interacts with other materials. Proper precautions must be taken when working with or storing hydrogen in order to prevent accidents and maintain safety for all involved.

The Basics of Hydrogen Storage

Hydrogen is a highly flammable gas that requires special storage conditions to ensure safety. The two primary methods of hydrogen storage are compressed gas and cryogenic liquid. Compressed gas storage involves storing the gas in high-pressure tanks, while cryogenic liquid storage involves cooling the gas to extremely low temperatures to convert it into a liquid state.

When considering hydrogen storage, it is important to take into account factors such as temperature, pressure, and volume. The ideal method of storage will depend on the specific application and required usage rate. While compressed gas tanks are more common for smaller-scale applications, larger-scale operations typically utilize cryogenic liquid storage due to its higher efficiency.

Proper hydrogen storage is essential for ensuring safety in any application involving the use of this highly reactive element. By understanding the basics of hydrogen storage, individuals can make informed decisions regarding the best method for their specific needs while minimizing risks associated with improper handling or accidents.

Common hydrogen safety issues to be aware of

Hydrogen may be odorless and colorless, but it can pose various safety concerns if proper precautions are not taken. Some common issues include hydrogen leaks, fires, and explosions.

A hydrogen leak can occur due to a malfunctioning valve or seal. Since hydrogen gas is highly flammable, leaks can lead to dangerous situations if not addressed immediately. Similarly, fires can occur when hydrogen comes into contact with an ignition source while under pressure. Explosions may also result from the rapid release of compressed hydrogen in an enclosed space.

To mitigate these risks, it is essential to have strict safety protocols in place for handling and storing hydrogen. This includes regular equipment maintenance and inspections as well as proper training for personnel working with the gas. By being aware of potential safety issues and taking proactive measures to prevent them, we can continue to safely utilize the benefits of hydrogen technology.

Tools and equipment for safe hydrogen handling

When it comes to handling hydrogen, it is essential to use the right tools and equipment to ensure maximum safety. Some of the most common tools required for safe hydrogen handling include pressure regulators, gauges, gas detectors, and flame arresters. These tools help to control the flow of hydrogen gas and minimize the risks associated with its use.

In addition to using specialized tools, it is also important to ensure that all equipment used in hydrogen storage and transportation are designed specifically for that purpose. This includes tanks, cylinders, piping systems, valves, fittings, and connectors. Using substandard or inadequate equipment can lead to accidents that can cause serious harm or damage.

Overall, taking care when selecting and maintaining the proper tools and equipment for hydrogen handling is crucial in ensuring a safe work environment where accidents are minimized or eliminated altogether.

Developing a Safety Protocol for Hydrogen Use

Developing and adhering to a safety protocol is critical to ensuring safe hydrogen use. The safety protocol should outline the steps involved in handling, storing, and transporting hydrogen safely. All personnel who work with hydrogen should receive proper training on the safety protocol and follow it closely at all times.

The safety protocol should also include emergency response procedures in case of any accidents or incidents involving hydrogen. These procedures should be well-planned and communicated clearly to all personnel involved. It is important to conduct regular safety drills to ensure that everyone knows what they need to do in an emergency situation.

In addition, regular equipment maintenance checks and inspections should be conducted as part of the safety protocol. Any faulty equipment or issues with storage tanks or pipes should be addressed immediately to prevent accidents from occurring.

A well-defined safety protocol can go a long way in preventing accidents and ensuring safe hydrogen use. By taking the necessary precautions, we can continue to harness the power of this clean energy source without compromising on our safety.

The Importance of Training and Education in Hydrogen Safety

When it comes to handling hydrogen safely, one of the most important factors is proper training and education. Without a thorough understanding of the risks involved and the best practices for safe handling, accidents can happen that put people and equipment at risk.

Training should cover a wide range of topics, from the properties of hydrogen and how it behaves in different situations to how to properly use tools and equipment for hydrogen handling. It is also important to understand safety protocols for responding to emergencies such as leaks or fires. Ongoing education is also crucial as new technology is developed, safety regulations change, and best practices evolve.

Investing in training and education not only helps prevent accidents but also promotes a culture of safety within an organization or industry. When everyone understands the importance of safe hydrogen handling, it becomes ingrained in daily operations leading to fewer incidents. Additionally, with proper training, individuals can become experts in their field which can lead to innovations that make hydrogen use even safer.

The Future of Hydrogen Safety Technology

As hydrogen continues to gain popularity as a clean energy source, it is important that safety measures keep pace with technological advancements. New technologies are emerging that promise to improve the safety and efficiency of hydrogen use.

One promising area of development is in the field of sensors. Advances in sensor technology will enable faster and more accurate detection of hydrogen leaks, which is crucial for preventing accidents. Additionally, new materials are being developed for hydrogen storage that have the potential to significantly reduce the risk of explosions.

Another area of focus is on developing better training programs for those working with hydrogen. Improved education and training will help ensure that those handling hydrogen are equipped with the knowledge and skills necessary to minimize risks and respond effectively in case of an emergency.

Overall, while there are still challenges to be addressed when it comes to hydrogen safety, there is reason for optimism as new technologies continue to emerge and improve. By staying informed about best practices and remaining committed to safety, we can continue moving toward a sustainable future powered by clean energy.

Our Services at TSM TheSafetyMaster Private Limited

HAZOP Study of Hydrogen Process

Quantitative Risk Assessment

Implementation of Process Safety Management

With Best Wishes

Sanjeev Paruthi

TSM TheSafetyMaster® Private Limited

Unit No 221-451-452, SPL1/J, 2nd Floor, Sunsquare Plaza Complex, RIICO Chowk, Bhiwadi 301019, Rajasthan, India

Phone: +91 1493 22 0093/+91-124-4881109

Mobile: +91 7665231743/9413882016

Email: info@thesafetymaster.com

SaferIndiaBetterWorld