Understanding the Vital Importance of Fire Adequacy Study and Designing in Manufacturing Industries: A Complete Guide

A Comprehensive Guide to Developing Process Safety Information for Process Industries in India

December 3, 2024

Implementing Pre-Startup Safety Reviews: Building a Solid Foundation for Safety Excellence in India’s Process Industries

December 5, 2024In this article, we will delve into the critical topic of fire adequacy study and design in manufacturing industries. As the backbone of our economy, these industries face unique challenges when it comes to fire safety, making it imperative for companies to thoroughly understand the subject matter. We will explore the importance of conducting comprehensive fire adequacy studies, highlighting potential risks, and identifying the most effective solutions. So, what can you expect from this complete guide? Brace yourself for a wealth of expert insights, in-depth analysis, and actionable advice, all aimed at ensuring the utmost fire safety in manufacturing environments. Join us on this enlightening journey as we promise to equip you with the necessary knowledge to safeguard your business and its employees.

Introduction

Fire safety is a paramount concern in manufacturing industries, where the potential risks and consequences of a fire outbreak can be devastating. Understanding and implementing effective fire adequacy study and design measures are crucial to safeguarding both the employees and the assets of these industries. In this comprehensive guide, we will delve into the vital importance of fire adequacy study and designing in manufacturing industries, exploring the various aspects that must be considered to ensure optimal fire safety. Throughout this article, we will explore key topics such as fire safety regulations, conducting risk assessments, developing prevention systems, employee training, emergency preparedness plans, and more. By delving into these essential areas, we aim to provide you with a complete understanding of how to effectively address fire safety concerns within manufacturing industries

The Significance of Fire Adequacy Study in Manufacturing Industries

The Significance of Fire Adequacy Study in Manufacturing Industries: In the intricate web of manufacturing industries, the significance of a comprehensive fire adequacy study cannot be overstated. It serves as an essential tool to safeguard human lives, protect valuable assets, and ensure uninterrupted operations. With the potential for devastating consequences, fires in manufacturing facilities can quickly escalate into catastrophic events if not adequately addressed.

A meticulous fire adequacy study goes beyond mere compliance with regulations; it strives to create a meticulously designed fire safety framework tailored to the unique requirements of each manufacturing facility. By identifying and mitigating potential fire hazards, such as flammable materials or faulty electrical systems, companies can proactively minimize risks and fortify their resilience against unforeseen emergencies.

Moreover, an optimized fire adequacy study bolsters employee morale by instilling a sense of safety and security within the workplace. When workers feel protected from potential fire outbreaks, they are more likely to be motivated and productive. Thus, investing in a thorough fire adequacy study not only fulfills legal obligations but also contributes to fostering a positive work environment that nurtures growth and prosperity.

Understanding Fire Safety Regulations and Standards

Understanding Fire Safety Regulations and Standards: Within the realm of manufacturing industries, adhering to fire safety regulations and standards is of utmost importance. These regulations are put in place to ensure the safety of employees, protect valuable assets, and prevent catastrophic incidents. Compliance with these regulations requires a deep understanding of fire safety codes set by local authorities, national bodies, and international organizations.

One such prominent regulatory body is the National Fire Protection Association (NFPA), which develops comprehensive codes and standards for fire prevention and protection. These codes cover various aspects, including building construction materials, electrical systems, storage arrangements, emergency exits, fire suppression systems, and more. Adherence to these codes not only enhances workplace safety but also instills confidence in employees that their well-being is prioritized.

Additionally, global standards such as ISO 45001 provide guidelines for implementing effective occupational health and safety management systems. By incorporating these standards into their practices, manufacturing industries can create a culture of safety that helps foster productivity and employee satisfaction. Remembering that a safe work environment leads to happier workers who perform better can be a motivating factor for companies seeking to comply with fire safety regulations.

Overall, understanding fire safety regulations and standards is essential for manufacturing industries to mitigate potential risks effectively. By keeping up-to-date with the evolving guidelines set by regulatory bodies like NFPA and embracing global standards like ISO 45001, companies not only ensure compliance but also cultivate an environment where employees feel secure in their surroundings – ultimately leading to increased productivity and overall success.

Identifying Potential Fire Hazards in Manufacturing Facilities

Identifying Potential Fire Hazards in Manufacturing Facilities: Within the vast expanse of manufacturing facilities, where innovation and productivity thrive, lies the inherent risk of potential fire hazards. Understanding these risks is paramount to ensuring the safety and well-being of all personnel involved in the manufacturing process. From flammable materials to faulty electrical systems, every nook and cranny demands meticulous scrutiny.

It is crucial to assess various aspects such as storage areas for combustible materials, electrical systems, machinery, and even human error when identifying potential fire hazards. Flammable liquids tucked away inappropriately or exposed wiring can act as potent triggers for catastrophic events. Furthermore, overlooking poor housekeeping practices or inadequate ventilation systems may exacerbate the risk further.

However, amidst these challenges lie opportunities for improvement and innovation. By conducting thorough inspections and risk assessments, manufacturers can proactively identify potential hazards before they escalate into life-threatening incidents. Implementing robust preventive measures such as proper material storage techniques, regular equipment maintenance schedules, and effective waste disposal protocols can significantly reduce the likelihood of fires occurring within manufacturing facilities

Conducting a Comprehensive Fire Risk Assessment

Conducting a Comprehensive Fire Risk Assessment: A thorough fire risk assessment is the cornerstone of any effective fire adequacy study in manufacturing industries. This crucial step involves meticulously examining the facility, identifying potential fire hazards, and evaluating their associated risks. It requires an astute understanding of the manufacturing processes and a keen eye for detail.

During the assessment, a team of experienced fire safety professionals meticulously inspects various aspects of the manufacturing facility. They analyse the layout, electrical systems, storage areas, ventilation systems, and any potential ignition sources. By assessing these elements comprehensively, they gain invaluable insights into how fire incidents could occur and spread within the premises.

Furthermore, this process enables them to determine vulnerable areas that require immediate attention and prioritize preventive measures accordingly. By conducting regular comprehensive assessments, manufacturers can proactively mitigate fire risks and ensure a safe working environment for their employees.

Remember, a proactive approach to fire risk assessment not only ensures compliance with regulations but also promotes a culture of safety within the organization. By investing in robust risk assessment procedures, manufacturers demonstrate their commitment to creating a secure environment that encourages employee well-being and protects valuable assets.

Developing Effective Fire Prevention, Detection, and Suppression Systems

Developing Effective Fire Prevention, Detection, and Suppression Systems: To ensure the utmost safety in manufacturing industries, developing robust fire prevention, detection, and suppression systems is of paramount importance. With the potential for devastating consequences that fires can inflict on personnel and property alike, diligent attention must be given to designing comprehensive measures that mitigate these risks.

Firstly, fire prevention strategies should focus on eliminating or minimizing factors that can ignite fires. This involves implementing stringent protocols for safe handling and storage of flammable materials, regular equipment maintenance to prevent electrical malfunctions, and proper training on fire safety practices for all employees.

Secondly, an efficient fire detection system is imperative in promptly identifying any signs of a fire outbreak. Modern technology offers advanced smoke detectors, heat sensors, and flame detectors that can provide early warnings to prevent fires from escalating. Integrating these devices with a centralized alarm system ensures quick response times in case of emergencies.

Lastly, effective suppression systems are vital for containing and extinguishing fires swiftly. This includes installing automatic sprinkler systems strategically throughout the facility to swiftly douse flames before they spread. Additionally, equipping designated personnel with portable fire extinguishers specific to different types of fires enhances the capacity to combat small-scale incidents immediately.

By carefully designing and implementing such comprehensive fire prevention measures along with robust detection and suppression systems within manufacturing facilities, companies demonstrate their unwavering commitment to safeguarding lives and preserving valuable assets. Such proactive efforts foster a culture of safety while providing peace of mind for all stakeholders involved.

Importance of Emergency Preparedness and Evacuation Plans

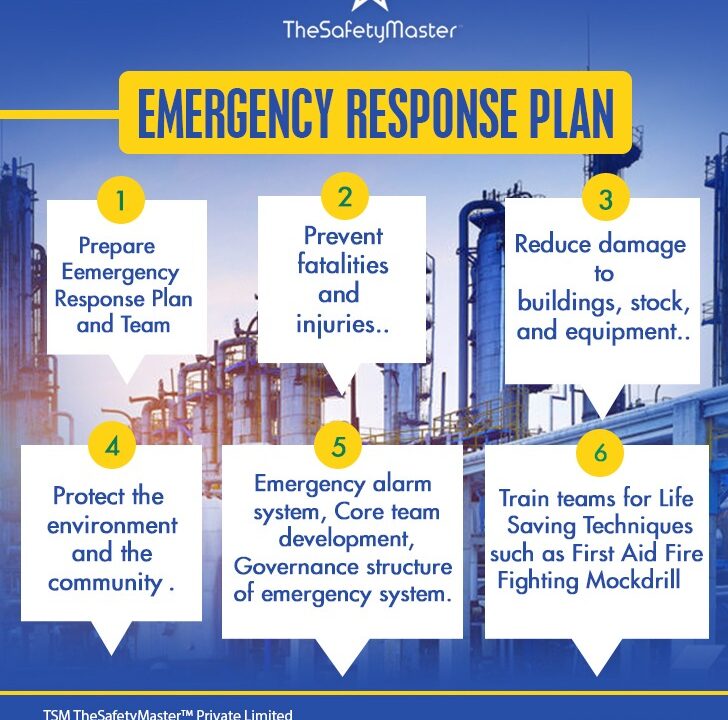

In times of crisis, a well-prepared emergency response can make all the difference. When it comes to fire safety in manufacturing industries, having robust emergency preparedness and evacuation plans is of paramount importance. These plans serve as guiding documents that outline the necessary steps and procedures to be followed in case of a fire incident, ensuring the safety and well-being of employees. One key aspect of emergency preparedness is conducting regular drills and training sessions to familiarize employees with evacuation procedures. By simulating real-life scenarios, workers gain confidence and readiness to respond swiftly and effectively during an actual emergency. This proactive approach not only instills a sense of security but also cultivates a culture of preparedness within the workforce.

Furthermore, an effective evacuation plan considers various factors such as the layout of the manufacturing facility, the number of exits available, and designated assembly points for employees. It is crucial to establish clear communication channels that facilitate prompt and accurate dissemination of information during emergencies. By providing employees with clear instructions on evacuation routes, assembly areas, and reporting protocols, companies can minimize panic and ensure a smooth evacuation process.

Remember, by prioritizing comprehensive emergency preparedness measures such as detailed evacuation plans, regular training sessions for staff members, and efficient communication protocols during crises; manufacturing industries can create safer work environments that prioritize employee well-being while fostering a positive organizational culture.

Training Employees for Fire Safety and Response

Section: Training Employees for Fire Safety and Response – In order to ensure a truly comprehensive fire safety plan, it is essential to invest in training employees on fire safety protocols and response strategies. By equipping your workforce with the necessary knowledge and skills, you empower them to become proactive guardians against potential fire hazards. Training sessions should cover a wide range of topics, including fire prevention techniques, proper handling of flammable materials, effective use of firefighting equipment, and evacuation procedures.

Engaging employees in realistic fire drills can further enhance their preparedness and confidence during emergencies. This practical experience allows them to understand the urgency of responding swiftly and calmly while following established evacuation routes. By instilling a sense of responsibility in every employee, you create a cohesive team that works together harmoniously to mitigate risks and minimize damage.

Remember that ongoing training is crucial as new employees join the workforce or existing staff members require refresher courses. Encourage participation by incorporating interactive elements such as quizzes or hands-on exercises. By fostering a culture of continuous learning and commitment to fire safety, your organization will thrive as a resilient fortress against potential fire threats.

Maintaining and Inspecting Fire Safety Equipment

Maintaining and Inspecting Fire Safety Equipment: Ensuring the proper maintenance and regular inspection of fire safety equipment is paramount in manufacturing industries. Fire extinguishers, sprinkler systems, smoke detectors, and emergency lighting all play vital roles in safeguarding against potential fire outbreaks. Regular inspections help identify any malfunctions or damage that could compromise the effectiveness of these crucial tools.

When it comes to maintaining fire safety equipment, a proactive approach is essential. Regular servicing by qualified professionals guarantees that all components are in optimal working condition. Additionally, conducting routine inspections ensures that any defects or issues are promptly addressed, minimizing the risk of failure during an emergency.

By investing time and resources into maintaining and inspecting fire safety equipment, manufacturing industries demonstrate their commitment to the safety and well-being of their employees. This diligence not only increases preparedness but also provides a sense of reassurance among workers. Knowing that proper measures are in place to prevent and fight fires fosters a positive work environment where employees can focus on their tasks with peace of mind.

Integrating Fire Adequacy Design Principles into Manufacturing Processes

Integrating Fire Adequacy Design Principles into Manufacturing Processes: Within the realm of manufacturing industries, the integration of fire adequacy design principles holds immense importance. By infusing these principles into their processes, companies can ensure not only the safety of their employees and assets but also optimize their operational efficiency. Fire adequacy design encompasses various aspects, including facility layout, material selection, equipment placement, and workflow optimization.

One key aspect is the careful selection of fire-resistant materials for constructing manufacturing facilities. Utilizing flame-retardant building materials and coatings can significantly reduce the risk of fire spread and limit potential damage. Additionally, implementing efficient ventilation systems that prioritize smoke extraction can help maintain visibility within the premises during a fire incident.

Another crucial consideration is designing an effective emergency response plan tailored specifically to the manufacturing environment. This involves establishing clear evacuation routes, strategically placing emergency exits, and ensuring accessibility to firefighting equipment throughout the facility. Regular drills and training sessions should be conducted to familiarize employees with proper response protocols in case of a fire emergency.

Moreover, integrating advanced technologies like automated fire detection systems and suppression equipment further enhances safety measures. Incorporating intelligent sensors that detect heat or smoke can provide early warnings and enable swift action before a fire escalates. Suppression systems such as sprinklers or gas-based extinguishing agents ensure quick containment while minimizing water or chemical damage.

By implementing these comprehensive fire adequacy design principles throughout their manufacturing processes, companies not only safeguard lives but also protect valuable investments and maintain business continuity. Such proactive measures instill confidence among stakeholders and promote sustainable growth within the industry while fostering a secure working environment for all.

Collaborating with Fire Safety Experts and Authorities

Collaborating with Fire Safety Experts and Authorities: In the intricate realm of fire safety, it is crucial for manufacturing industries to seek guidance from seasoned fire safety experts and authorities. These individuals possess a profound understanding of the complex dynamics involved in preventing and combatting fires within industrial settings. By collaborating with these experts, manufacturers can benefit from their wealth of knowledge and experience, ensuring that their fire adequacy study is comprehensive and effective.

Fire safety experts bring invaluable insights when it comes to assessing potential fire hazards specific to manufacturing facilities. Their discerning eye can identify hidden risks that may elude the untrained observer. Through careful evaluation of processes, materials, and equipment, these experts can help manufacturers implement proactive measures to minimize fire risks.

Furthermore, working closely with fire safety authorities ensures compliance with local regulations and standards. Collaborating with these entities establishes a productive relationship where manufacturers can gain vital advice on adhering to legal requirements while going beyond mere compliance in order to foster a culture of enhanced fire safety within their facilities.

Remember, collaboration not only brings expert perspectives but also strengthens the commitment towards improved fire safety measures. By joining forces with these professionals, manufacturers demonstrate their dedication to protecting lives, preserving assets, and fostering a safe environment for both employees and stakeholders. Embracing this collaborative approach instills confidence within the industry while paving the way for continuous advancements in fire prevention techniques.

Case Studies: Successful Implementation of Fire Adequacy Study in Manufacturing Industries

Case Studies: Successful Implementation of Fire Adequacy Study in Manufacturing Industries- In the realm of fire safety, real-life examples speak louder than words. Let us now delve into a few case studies that demonstrate the successful implementation of fire adequacy study in manufacturing industries, igniting a sense of inspiration and optimism.

One noteworthy case comes from a large-scale automotive manufacturing plant that was able to mitigate potential fire hazards through a comprehensive fire adequacy study. By conducting a thorough assessment, they identified critical areas where fire risks were high, such as storage facilities and production lines. Implementing state-of-the-art fire prevention systems, including automated extinguishing agents and early detection devices, they significantly reduced the chances of fire outbreaks. This proactive approach not only safeguarded their employees but also showcased their commitment to ensuring uninterrupted production processes.

In another remarkable case, a leading pharmaceutical company implemented an exemplary fire adequacy study across its sprawling manufacturing complex. By collaborating with experts in fire safety engineering, they analyzed every inch of their facility to identify potential ignition sources and optimize escape routes. They emphasized employee training programs to enhance awareness and response skills. With the incorporation of advanced suppression systems tailored to their specific needs, such as gas-based extinguishing agents for sensitive laboratory environments, they achieved an unmatched level of preparedness. This success story highlights how meticulous planning can revolutionize safety measures within manufacturing industries.

These case studies affirm that investing time and resources into fire adequacy studies can yield extraordinary results in protecting the well-being of both employees and assets. Through proactive measures grounded in expert analysis and innovation, manufacturing industries are fostering safer work environments while maintaining efficient operations—a testament to the power of comprehensive fire safety protocols.

Conclusion

In conclusion, incorporating fire adequacy study and design principles in manufacturing industries is paramount for the safety of employees, protection of assets, and continuity of operations. By understanding fire safety regulations, identifying potential hazards, conducting risk assessments, implementing prevention measures, and training employees effectively, organizations can significantly reduce the risks associated with fire incidents. Moreover, maintaining and inspecting fire safety equipment regularly ensures their operational readiness when needed most. By embracing these practices and collaborating with fire safety experts and authorities, manufacturing industries can create a robust fire safety framework that safeguards lives and property. Let us forge ahead with a renewed commitment to prioritizing fire adequacy study to build resilient manufacturing spaces that foster productivity while ensuring the well-being of all stakeholders.